2022 China New Design Export Galvanized Wire Production Line – Double Twist Bunching Machine PengSheng

2022 China New Design Export Galvanized Wire Production Line – Double Twist Bunching Machine PengSheng Detail:

Double Twist Bunching Machine

For precision control and easy operation, AC technology, PLC & inverter control and HMI are applied in our double twist bunching machines. Meanwhile a variety of safety protection guarantee our machine running with high performance.

1. Double Twist Bunching Machine (Model: OPS-300D- OPS-800D)

Application: Main suitable for twisting above 7 strands of the silver jacketed wire, tinned wire, enameled wire, bare copper wire, copper-clad steel, copper cladding aluminum, etc. Left or right twisting direction can be selected freely.

| Model | OPS-300D | OPS-400D/ OPS -500D | OPS-630D | OPS-800D | OPS-800D |

| spool dia.(mm) | 300 | 400-500 | 630 | 800 | 1000 |

| max rotating speed (rpm) | 3000 | 3000 | 2000 | 2000 | 1500 |

| feeding wire dia. (mm) | 0.05-0.28 | 0.08- 0.45 | 0.12- 0.62 | 0.2-1.04 | 0.45-2.52 |

| twist cross section(mm²) | 0.035-0.45 | 0.035-2.5 | 0.18-6.0 | 0.8-16 | 6-35 |

| lay length(mm) | 10 Segment3.65-17.15 | 40 Segment6.3-50.4 | 34 Segment11.15-100 | 30 Segment20-160 | 34 Segment20-300 |

2, Double Twist Bunching Machine (Model: OPS-1250D – OPS -2500D)

Application: Main suitable for twisting copper wire, aluminum wire or PVC insulated wire below 7/19/37/61 strands to concentric twisting wire.

| Model | OPS-1250D | OPS -1600D | OPS -1800D | OPS -2000D | OPS -2240D | OPS -2500D |

| max. spool dia.(mm) | 1250 | 1600 | 1800 | 2000 | 2240 | 2500 |

| max. line speed(m/min) | 70-150 | 170-200 | 170-200 | 170-200 | 170-200 | 170-200 |

| max rotating speed (rpm) | 800 | 600 | 350 | 350 | 300 | 300 |

| feeding wire dia. (Al/Cu) (mm) | 1.0-3.0 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 |

| stand cross section(mm²) | 3.5-70 | 16-240 | 16-240 | 16-240 | 16-240 | 16-240 |

| compacting section (Cu) ( mm²) | 3.5-50 | 16-150 | 16-185 | 16-240 | 16-300 | 16-300 |

| compacting section (Al) ( mm²) | 3.5-70 | 16-240 | 16-240 | 16-300 | 16-400 | 16-400 |

| lay length(mm) | 40-350 | 40-350 | 50-600 | 60-600 | 60-600 | 60-600 |

| max. strand outer dia. (mm) | 15 | 25 | 35 | 35 | 35 | 35 |

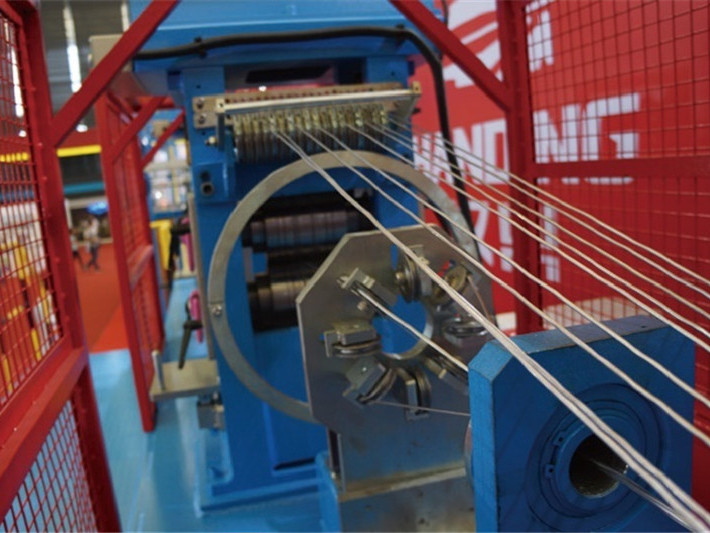

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of 2022 China New Design Export Galvanized Wire Production Line – Double Twist Bunching Machine PengSheng , The product will supply to all over the world, such as: Congo, Italy, Mozambique, Qualified R&D engineer might be there for your consultation service and we will try our best to meet your requirements. So you should feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we are going to surely present you with the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we'll make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we're here to welcome your inquiries for any of our merchandise and service.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.

Write your message here and send it to us