2022 Good Quality Co2 Welding Wire Production Line - Flux Cored Welding Wire Production Line PengSheng

2022 Good Quality Co2 Welding Wire Production Line - Flux Cored Welding Wire Production Line PengSheng Detail:

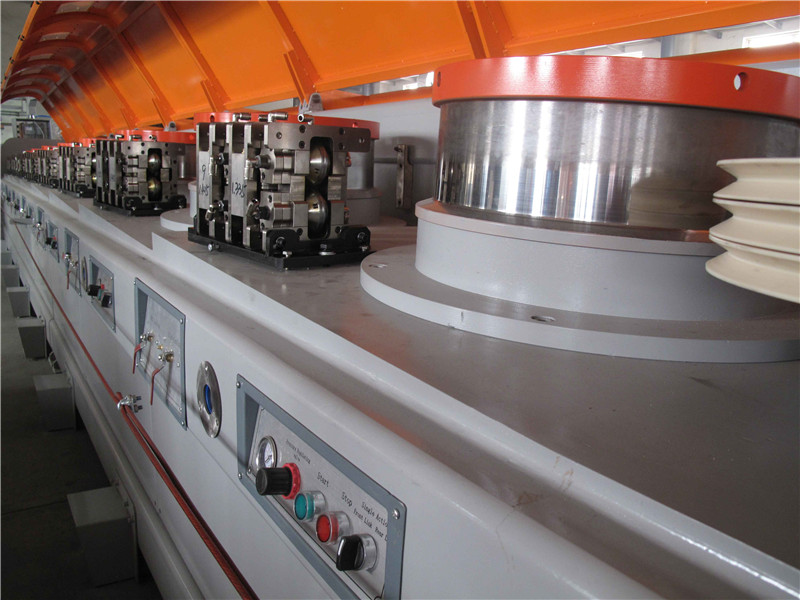

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

● Forming machine with powder feeding system

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for 2022 Good Quality Co2 Welding Wire Production Line - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: venezuela, Sevilla, Luxemburg, To get more information about us as well as see all our products, please visit our website. To get more information please feel free to let us know. Thank you very much and wish your business always be great!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.

Write your message here and send it to us