2022 Good Quality Continuous Cladding Machine - Horizontal DC Resistance Annealer PengSheng

2022 Good Quality Continuous Cladding Machine - Horizontal DC Resistance Annealer PengSheng Detail:

Productivity

• annealing voltage could be chose to meet different wire requirement

• single or double wire path design to meet different drawing machine

Efficiency

• water cooling of contact wheel from inner to outside design improves the service life of bearings and nickel ring effectively

| Type | TH5000 | STH8000 | TH3000 | STH3000 |

| No. of wires | 1 | 2 | 1 | 2 |

| Inlet Ø range [mm] | 1.2-4.0 | 1.2-3.2 | 0.6-2.7 | 0.6-1.6 |

| Max. speed [m/sec] | 25 | 25 | 30 | 30 |

| Max. annealing power (KVA) | 365 | 560 | 230 | 230 |

| Max. annealing voltage (V) | 60 | 60 | 60 | 60 |

| Max. annealing current (A) | 5000 | 8000 | 3000 | 3000 |

| Protection system |

nitrogen or steam atmosphere |

|||

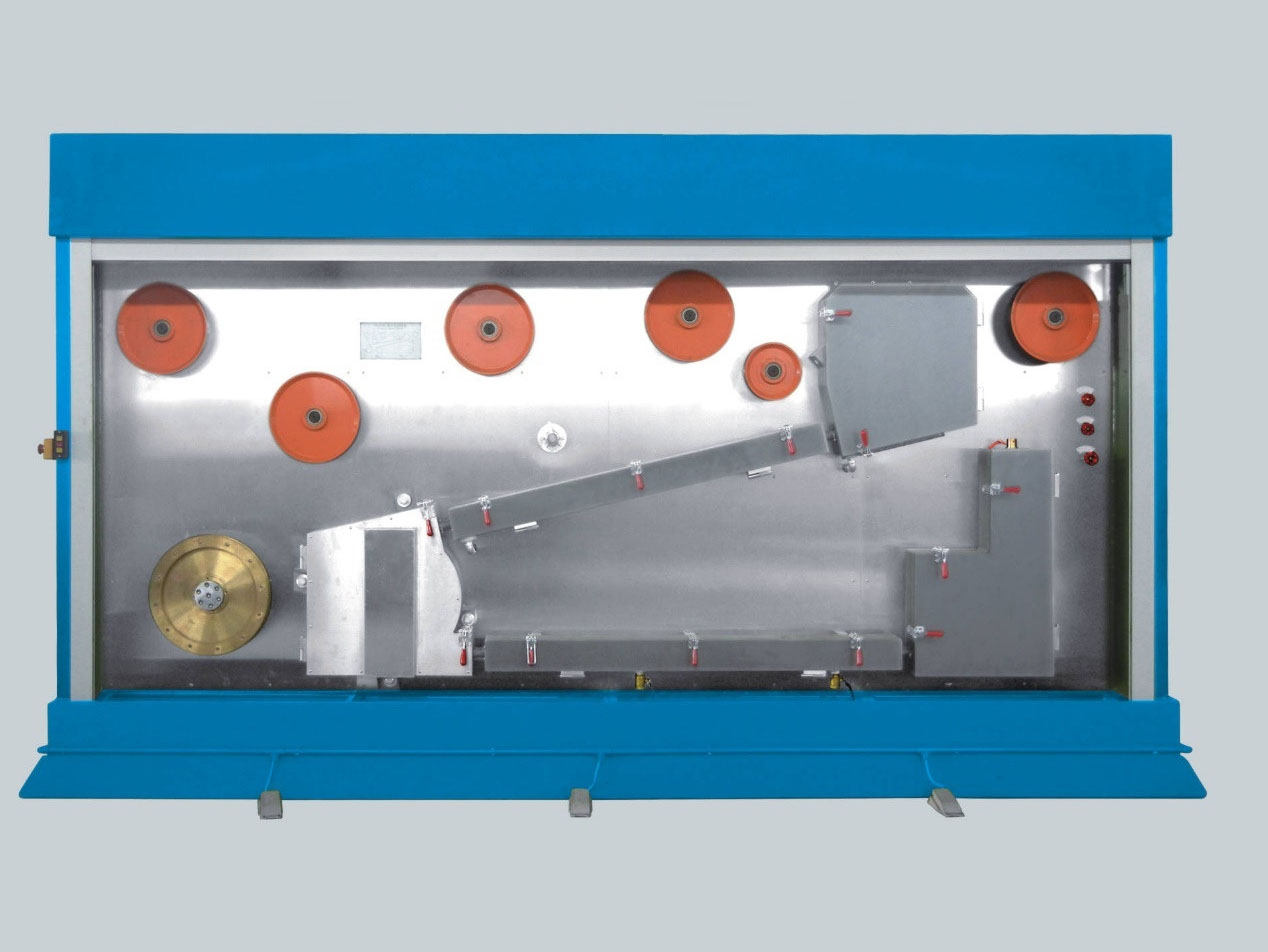

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for 2022 Good Quality Continuous Cladding Machine - Horizontal DC Resistance Annealer PengSheng , The product will supply to all over the world, such as: America, Juventus, Argentina, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Write your message here and send it to us