2022 Good Quality Fine Copper Wire Drawing Machine - Dry Steel Wire Drawing Machine PengSheng

2022 Good Quality Fine Copper Wire Drawing Machine - Dry Steel Wire Drawing Machine PengSheng Detail:

Features

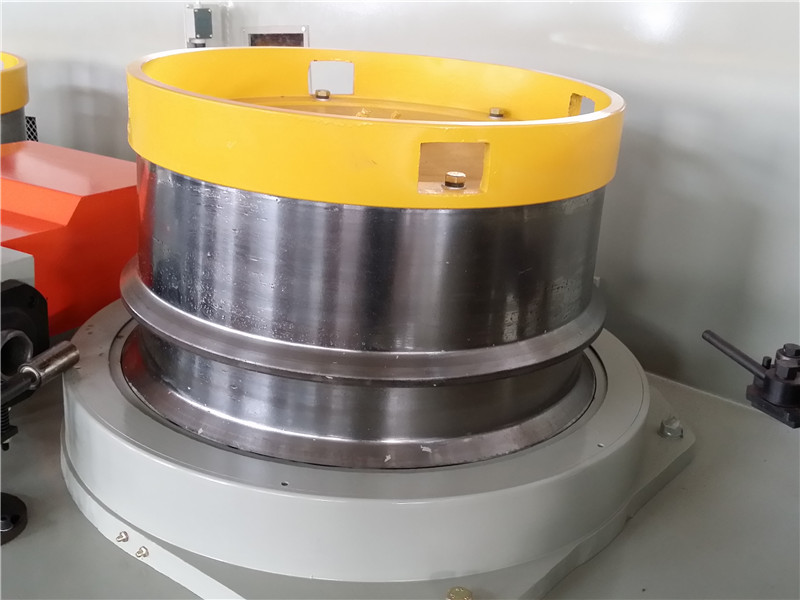

● Forged or casted capstan with hardness of HRC 58-62.

● High efficiency transmission with gear box or belt.

● Movable die box for easy adjustment and easy die changing.

● High performance cooling system for the capstan and die box

● High safety standard and friendly HMI control system

Available options

● Rotating die box with soap stirrers or rolling cassette

● Forged capstan and tungsten carbide coated capstan

● Accumulation of first drawing blocks

● Block stripper for coiling

● First level international electrical elements

Main technical specifications

|

Item |

LZn/350 |

LZn/450 |

LZn/560 |

LZn/700 |

LZn/900 |

LZn/1200 |

|

Drawing Capstan |

350 |

450 |

560 |

700 |

900 |

1200 |

|

Max. Inlet Wire Dia.(mm) |

4.3 |

5.0 |

7.5 |

13 |

15 |

20 |

|

Max. Inlet Wire Dia.(mm) |

3.5 |

4.0 |

6.0 |

9 |

21 |

26 |

|

Min. Outlet Wire Dia.(mm) |

0.3 |

0.5 |

0.8 |

1.5 |

2.4 |

2.8 |

|

Max. Working Speed(m/s) |

30 |

26 |

20 |

16 |

10 |

12 |

|

Motor Power(KW) |

11-18.5 |

11-22 |

22-45 |

37-75 |

75-110 |

90-132 |

|

Speed Control |

AC variable frequency speed control |

|||||

|

Noise Level |

Less than 80 dB |

|||||

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater quality, lessen processing costs, price ranges are much more reasonable, won the new and outdated shoppers the support and affirmation for 2022 Good Quality Fine Copper Wire Drawing Machine - Dry Steel Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Cologne, Sacramento, Qatar, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.