2022 Good Quality Wire Fiberglass Insulating Machine - Horizontal Taping Machine-Single Conductor PengSheng

2022 Good Quality Wire Fiberglass Insulating Machine - Horizontal Taping Machine-Single Conductor PengSheng Detail:

Main technical data

Conductor area: 5 mm²—120mm²(or customized)

Covering layer: 2 or 4 times of layers

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

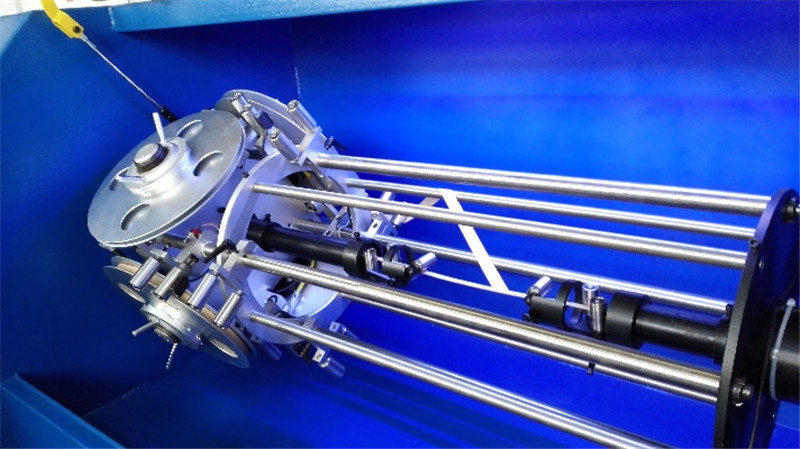

Taping head

Caterpillar

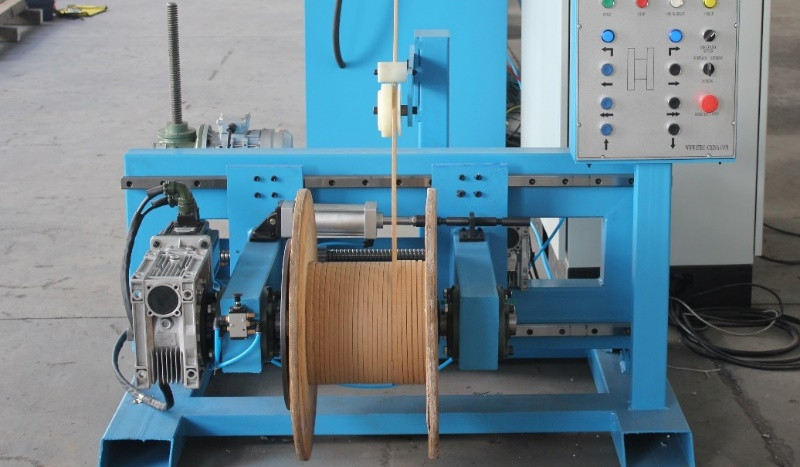

Take-up

Product detail pictures:

Related Product Guide:

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for 2022 Good Quality Wire Fiberglass Insulating Machine - Horizontal Taping Machine-Single Conductor PengSheng , The product will supply to all over the world, such as: Kenya, Ecuador, Bolivia, The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.

Write your message here and send it to us