2022 High quality Continuous Extrusion And Cladding/Sheathing Machinery - High-Efficiency Intermediate Drawing Machine PengSheng

2022 High quality Continuous Extrusion And Cladding/Sheathing Machinery - High-Efficiency Intermediate Drawing Machine PengSheng Detail:

Productivity

• touchscreen display and control, high automatic operation

• single or double wire path design to meet different production requirements

Efficiency

• meets different finished product diameters

•force cooling/ lubrication system and sufficient protection technology for transmission to safeguard machine with long service life

Main technical data

| Type | ZL250-17 | ZL250B-17 | DZL250-17 | DZL250B-17 |

| Material | Cu | Al/Al-Alloys | Cu | Al/Al-Alloys |

| Max inlet Ø [mm] | 3.5 | 4.2 | 3.0 | 4.2 |

| Outlet Ø range [mm] | 0.32-2.76 | 0.4-2.76 | 0.4-2.0 | 0.4-2.0 |

| No. of wires | 1 | 1 | 2 | 2 |

| No. of drafts | 9/17 | 9/17 | 9/17 | 9/17 |

| Max. speed [m/sec] | 30 | 30 | 30 | 30 |

| Wire elongation per draft | 18%-25% | 13%-18% | 18%-25% | 13%-18% |

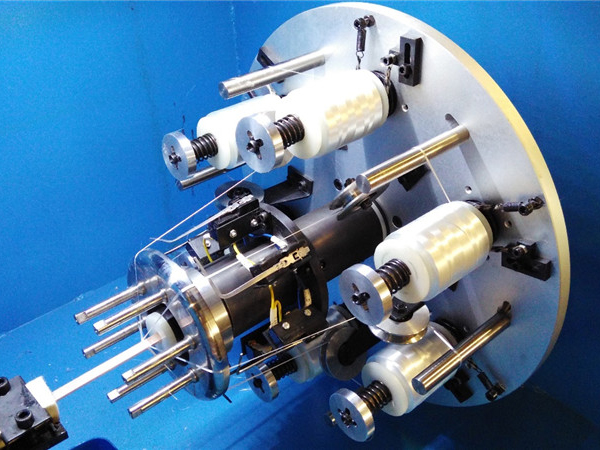

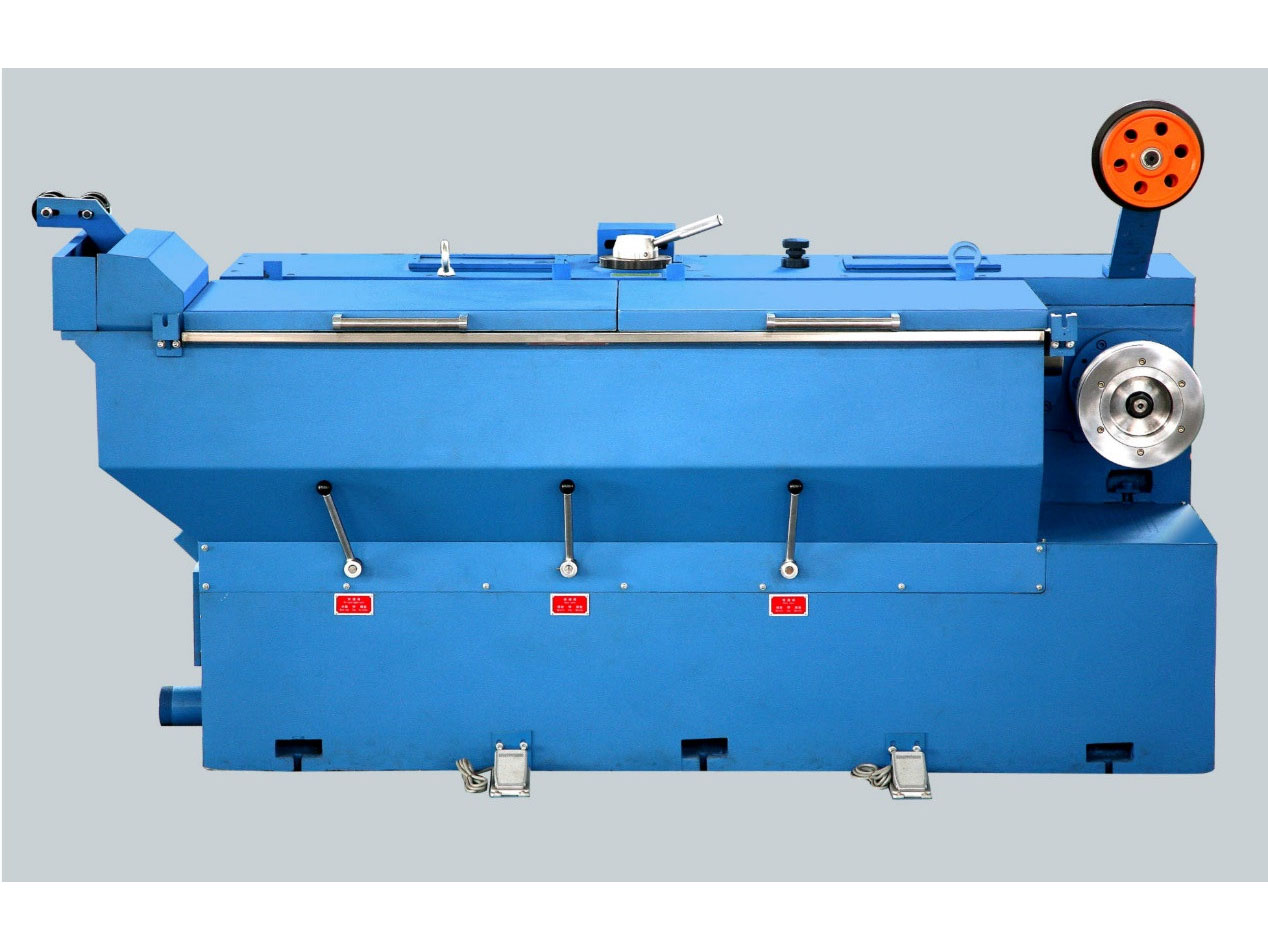

Product detail pictures:

Related Product Guide:

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for 2022 High quality Continuous Extrusion And Cladding/Sheathing Machinery - High-Efficiency Intermediate Drawing Machine PengSheng , The product will supply to all over the world, such as: British, Costa rica, Suriname, Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us