2022 High quality Continuous Extrusion And Cladding/Sheathing Machinery - High-Efficiency Multi Wire Drawing Line PengSheng

2022 High quality Continuous Extrusion And Cladding/Sheathing Machinery - High-Efficiency Multi Wire Drawing Line PengSheng Detail:

Productivity

• quick drawing die change system and two motor-driven for easy operation

• touchscreen display and control, high automatic operation

Efficiency

• power saving, labor saving, wire drawing oil and emulsion saving

•force cooling/ lubrication system and sufficient protection technology for transmission to safeguard machine with long service life

• meets different finished product diameters

•meeting different production requirements

Multiwire Annealer:

• DC multiwire resistance annealer

• DC contact type, 2or 3 stage annealing system, automatic speed tracking system for guaranteeing the quality of product.

• separation design of contact tubes for changing convenience, nickel plating and polishing to the surface of contact tubes for long service life

• nitrogen or steam protection system for preventing oxidization

• individual spray cooling unit for each annealed wire

| Multiwire drawing machine | |||

| Type | DZL16-18-8 | DXL21-25-8 | DXL21-25-16 |

| Max inlet Ø [mm] | 2.6*8 | 1.8-2.0*8 | 2.6*8,2.0*16 |

| Outlet Ø range [mm] | 0.4-1.05 | 0.15-0.5 | 0.15-1.05 |

| No. of wires | 8 | 8 | 16 |

| Max. speed [m/sec] | 30 | 30 | 30 |

| Wire elongation per draft | 8-25% | 8-25% | 8-25% |

| Multiwire Annealer | |||

| Max. annealing power (KVA) | 230/285 | 100 | 230/285 |

| Max. annealing current (A) | 3000/4000 | 1500 | 3000/4000 |

| Saturation wire diameter (mm) | 0.4-0.8 | 0.15-0.5 | 0.15-0.5 |

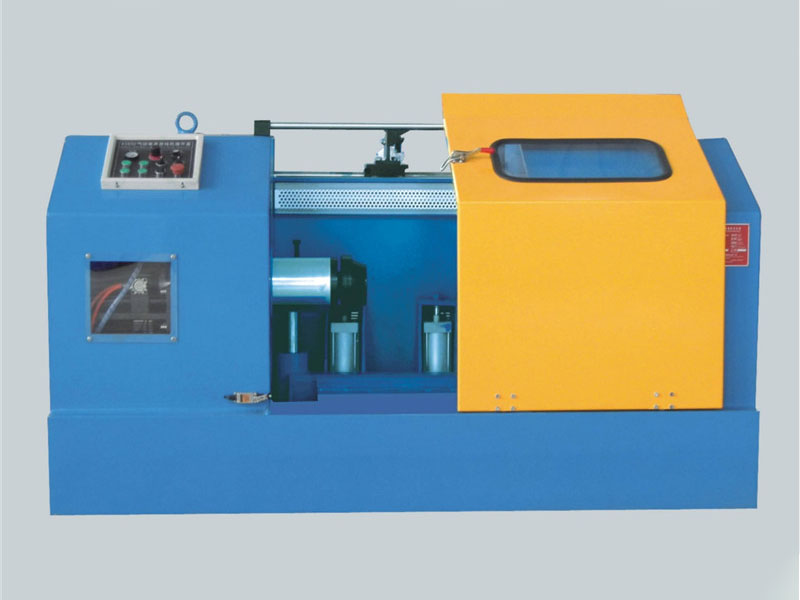

Product detail pictures:

Related Product Guide:

Reliable good quality and very good credit standing are our principles, which will help us at a top-ranking position. Adhering to your tenet of "quality 1st, purchaser supreme" for 2022 High quality Continuous Extrusion And Cladding/Sheathing Machinery - High-Efficiency Multi Wire Drawing Line PengSheng , The product will supply to all over the world, such as: Surabaya, Germany, Malaysia, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a really should in your case of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we've been planning to possess a vibrant prospect and to be distributed all over the world within the years to come.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!