2022 High quality Wire Extruder - Single Twist Stranding Machine PengSheng

2022 High quality Wire Extruder - Single Twist Stranding Machine PengSheng Detail:

Single Twist Stranding Machine

We produce two different kind of single twist stranding machine:

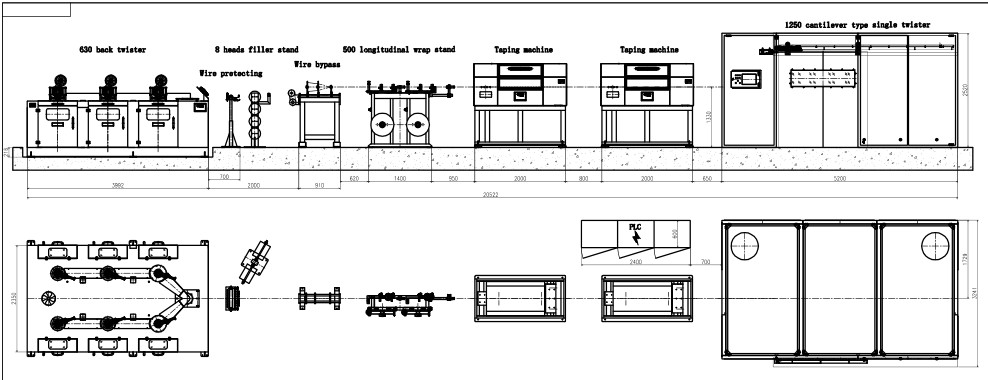

•Cantilever type for spools from dia.500mm up to dia.1250mm

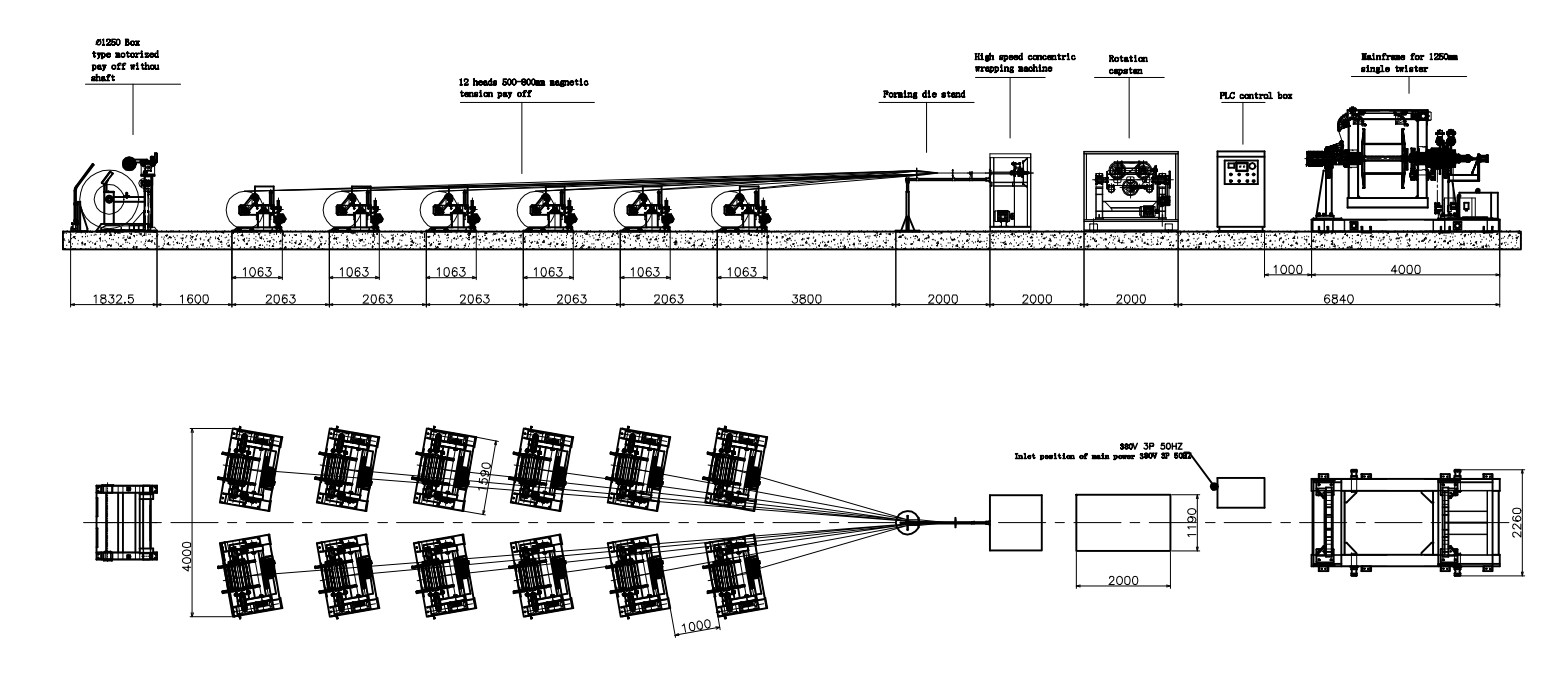

•Frame type for spools from dia. 1250 up to d.2500mm

1.Cantilever type single twist stranding machine

It is suitable for various power wire, CAT 5/CAT 6 data cable, communication cable and other special cable twisting.

| Model | OPS -500 | OPS -630 | OPS -800 | OPS -1000 | OPS -1250 |

| max. spool dia.(mm) | 500 | 630 | 800 | 1000 | 1250 |

| max rotating speed (rpm) | 750 | 750 | 650 | 600 | 400 |

| Feeding wire dia. | 0.5-2.0 | 0.6-3.0 | 0.6-3.0 | 1.0-5.0 | 1.0-5.0 |

| max. twisted dia. (mm) | 6 | 12 | 16 | 20 | 25 |

| Lay length(mm) | 13-80 | 20-200 | 30-300 | 30-350 | 30-350 |

2.Frame type single twist stranding machine

It is suitable for copper conductor, insulated cable, armored and shielded power cable, etc. twisting.

| Model | OPS -1250 | OPS -1600 | OPS -2000 | OPS -2240 | OPS -2500 |

| max. spool dia.(mm) | 1250 | 1600 | 2000 | 2240 | 2500 |

| max rotating speed (rpm) | 450 | 350 | 350 | 350 | 350 |

| max. twisted dia. (mm) | 30 | 35 | 40 | 45 | 50 |

Product detail pictures:

Related Product Guide:

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for 2022 High quality Wire Extruder - Single Twist Stranding Machine PengSheng , The product will supply to all over the world, such as: Melbourne, Hyderabad, Chile, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

Write your message here and send it to us