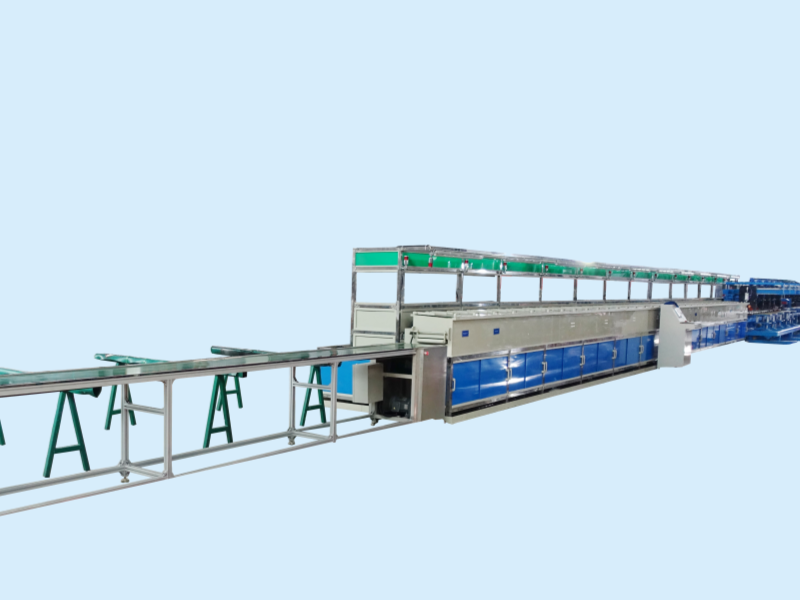

Automatic Continuous Copper Busbar Tin Plating Machine

Main technical data

| MODEL | OCTP300 |

| Copper busbar width range | 20-150 mm*2 |

| Copper busbar length range | ≥4000mm |

| Copper busbar thickness range | 3-20mm |

| Tinning layer thickness range | 0-3 um, adjustment |

| Production speed | 5-20 m /min, adjustment (calculate as 6*60 mm busbar, plating with 1-3µm, around 1-3T/h) |

| Total installing power | ≈100 kW (include filter and rectifier) |

| Actual running power | ≈50-80 kW (include filter and rectifier) |

| Dimension | 30*2.0*2.2m |

| MODEL | OCTP600 |

| Copper busbar width range | 15-150 mm*2 |

| Copper busbar length range | ≥3000mm |

| Copper busbar thickness range | 3-20mm |

| Tinning layer thickness range | 0-12 um, adjustment |

| Production speed | 5-20 m /min, adjustment (calculate as 6*60mm, 3 strips busbar, plating with 5µm, around 2T/h) |

| Total installing power | ≈310 kW (include filter and rectifier) |

| Actual running power | ≈180 kW (include filter and rectifier) |

| Dimension | 35.5*2.0*2.2m |

Advantages

● The line changes the way of traditional hanging plating to conventional way, which improves the efficiency, surface quality and performance of the plating corrosion resistance.

● Small floor space, low flux consumption, environment friendly, and advanced production process, etc.

● The cleaning and plating section are all automatic running, only needs feeding and packing manpower for the line.

● The line also could be equipped with feeding and offloading mechanical arm which can matched with the hydraulic drawing machine.

● This line works in a closed condition and trough stepless speed regulation microcomputer to control, the busbar gets continuously tin plated under high density of current.

● The waste air treatment ratio is more than 98% and waste water treatment ratio is 100%.

● Multi pieces busbars can be plated synchronously when busbar width is less than 150 mm.

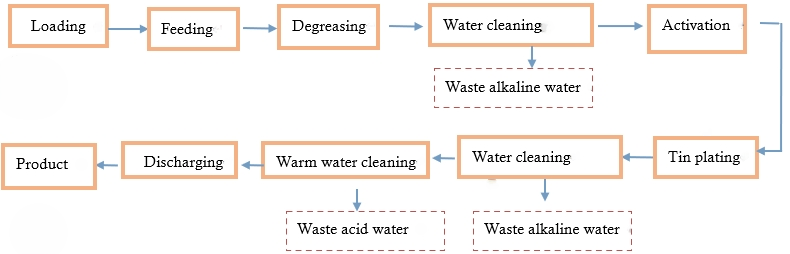

Brief process flow