Best quality High Speed Co2 Welding Wire Line Processing Machine - Flux Cored Welding Wire Production Line PengSheng

Best quality High Speed Co2 Welding Wire Line Processing Machine - Flux Cored Welding Wire Production Line PengSheng Detail:

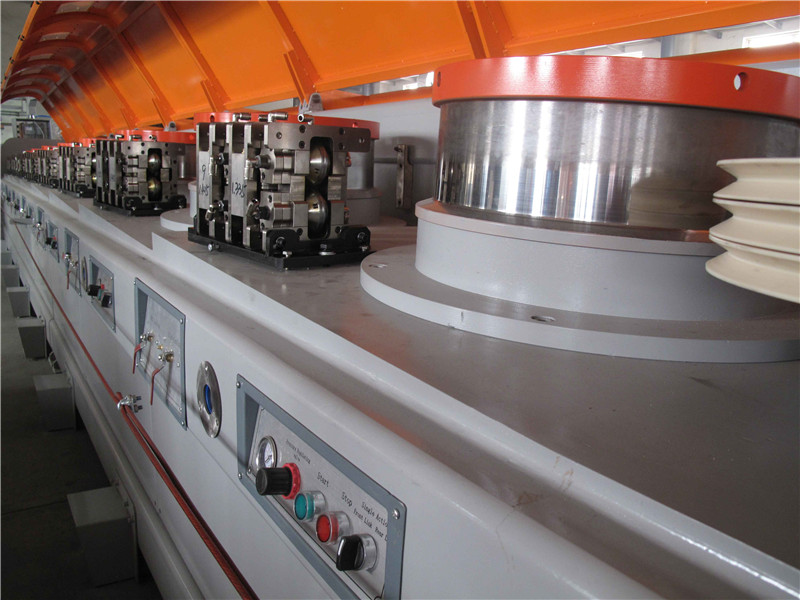

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

● Forming machine with powder feeding system

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

We constantly believe that one's character decides products' high quality, the details decides products' high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Best quality High Speed Co2 Welding Wire Line Processing Machine - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: Azerbaijan, Cape Town, luzern, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

Write your message here and send it to us