Big discounting Cable Extrusion Machine - Continuous Cladding Machinery PengSheng

Big discounting Cable Extrusion Machine - Continuous Cladding Machinery PengSheng Detail:

Principle

The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die to form a metal sheath without contacting the wire core (sheathing). Double-wheel cladding/sheathing uses two extrusion wheels to provide four rods to clad/sheath large diameter wire core.

| Model | SLB 350 | SLB400 | SSLB500(Double wheels) |

| Cladding | |||

| main motor power(kw) | 200 | 400 | - |

| feeding rod dia. (mm) | 2*9.5 | 2*12 | - |

| core wire dia. (mm) | 3-7 | 3-7 | - |

| line speed (m/min) | 180 | 180 | - |

| Sheathing | |||

| main motor power(kw) | 160 | 250 | 600 |

| feeding rod dia. (mm) | 2*9.5 | 2*9.5/2*12 | 4*15 |

| core wire dia. (mm) | 4-28 | 8-46 | 50-160 |

| sheath thickness (mm) | 0.6-3 | 0.6-3 | 2-4 |

| sheath outer dia. (mm) | 6-30 | 20-50 | 60-180 |

| line speed (m/min) | 60 | 60 | 12 |

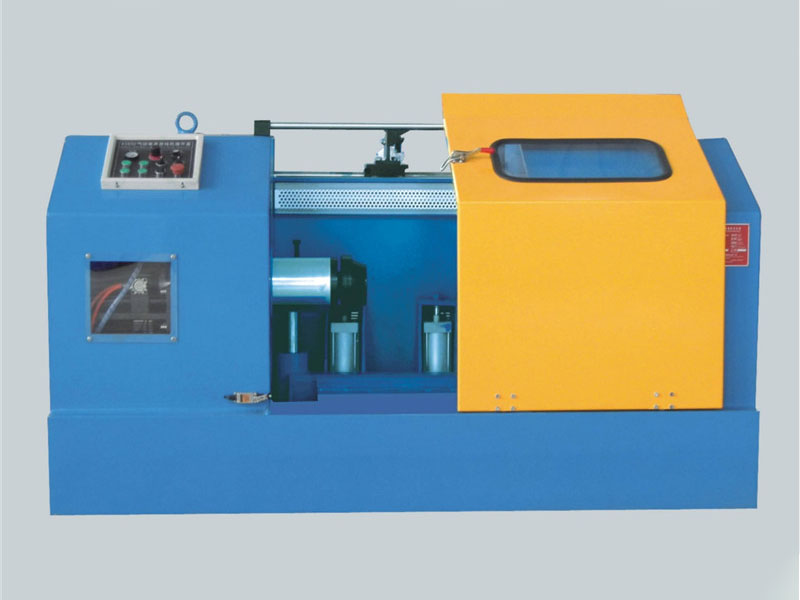

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Big discounting Cable Extrusion Machine - Continuous Cladding Machinery PengSheng , The product will supply to all over the world, such as: Cape Town, Doha, Belgium, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

Write your message here and send it to us