China Cheap price Cable And Conductor Taping Machine - Fiber Glass Insulating Machine PengSheng

China Cheap price Cable And Conductor Taping Machine - Fiber Glass Insulating Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 800 rpm

Line speed: max. 8 m/min.

Special Characteristics

Servo drive for the winding head

Auto-stop when fiberglass broken

Rigid and modular structure design to eliminate vibration interaction

PLC control and touch screen operation

Overview

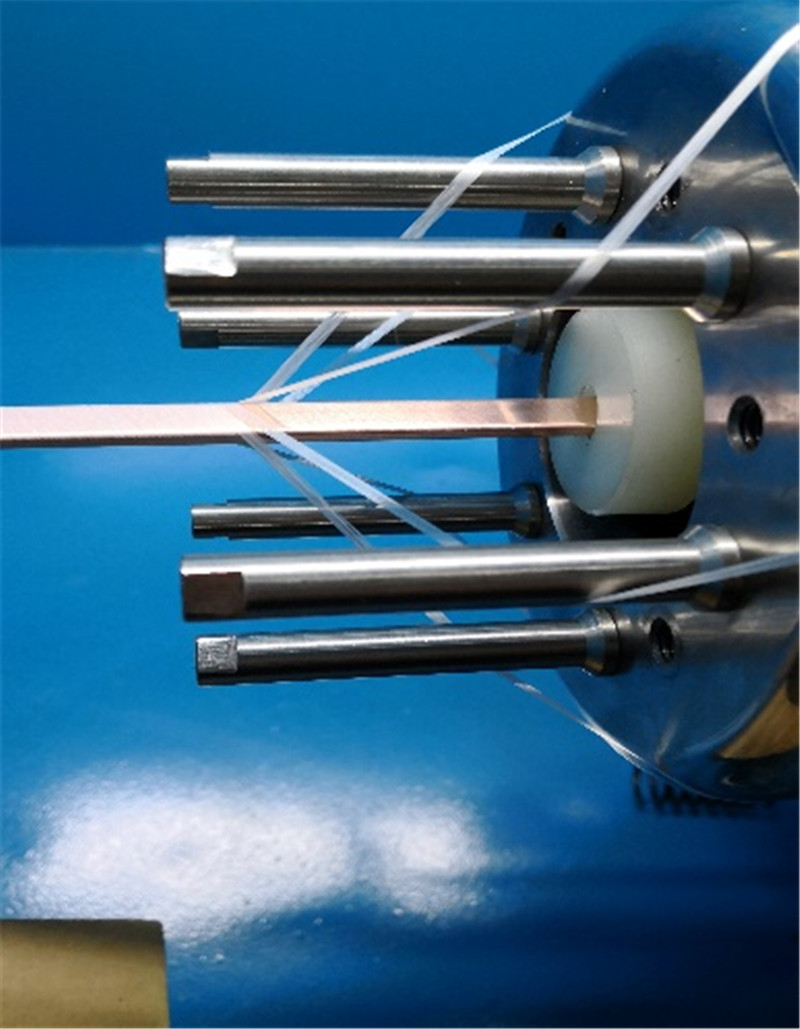

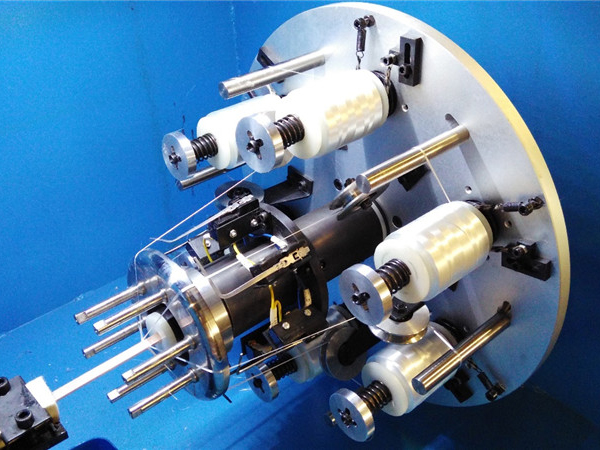

Taping

Oven

Product

Product detail pictures:

Related Product Guide:

We not only will try our greatest to present fantastic expert services to each purchaser, but also are ready to receive any suggestion offered by our prospects for China Cheap price Cable And Conductor Taping Machine - Fiber Glass Insulating Machine PengSheng , The product will supply to all over the world, such as: Mexico, Accra, Namibia, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!

Write your message here and send it to us