China Cheap price Vertical Annealer - Wire and Cable Automatic Coiling Machine PengSheng

China Cheap price Vertical Annealer - Wire and Cable Automatic Coiling Machine PengSheng Detail:

Characteristic

• It could be equipped with cable extrusion line or an individual pay-off directly.

• Servo motor rotation system of the machine can allow the action of wire arrangement more harmonious.

• Easy control by touch screen (HMI)

• Standard service range from coil O.D. 180mm to 800mm.

• Simple and easy to use machine with low maintenance cost.

| Model | Height(mm) | Outer diameter(mm) | Inner diameter(mm) | Wire diameter(mm) | Speed |

| OPS-0836 | 40-80 | 180-360 | 120-200 | 0.5-8 | 500M/min |

| OPS-1246 | 40-120 | 200-460 | 140-220 | 0.8-12 | 350M/min |

| OPS-1860 | 60-180 | 220-600 | 160-250 | 2.0-20 | 250M/min |

| OPS-2480 | 80-240 | 300-800 | 200-300 | 3.0-25 | 100M/min |

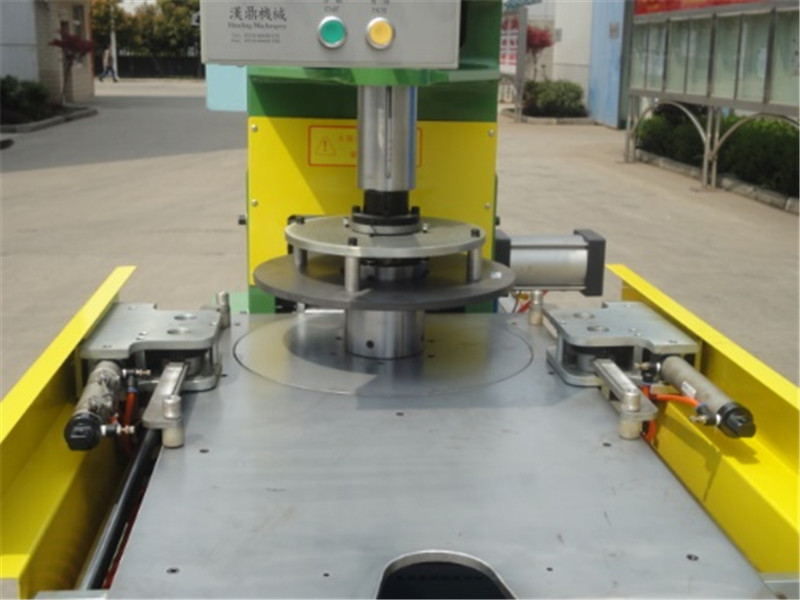

Product detail pictures:

Related Product Guide:

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for China Cheap price Vertical Annealer - Wire and Cable Automatic Coiling Machine PengSheng , The product will supply to all over the world, such as: Bangkok, Nigeria, Amman, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Write your message here and send it to us