China Gold Supplier for Hot-Dip Steel Wire Galvanizing Line - Steel Wire Drawing Machine-Auxiliary Machines PengSheng

China Gold Supplier for Hot-Dip Steel Wire Galvanizing Line - Steel Wire Drawing Machine-Auxiliary Machines PengSheng Detail:

Pay-offs

Hydraulic vertical pay-off: Double vertical hydraulic rod stems that easy for wire loaded and capable of continuous wire decoiling.

Horizontal pay-off: Simple payoff with two working stems that suitable for the high and low carbon steel wires. It could load two coils of rod that realize the continuous wire rod decoiling.

Overhead pay-off: Passive type pay-off for wire coils and equipped with the guiding rollers to avoid any wire disordered.

Spool pay-off: Motor driven pay-off with pneumatic spool fixing for stable wire decoiling.

Wire pretreatment devices

The wire rod must be cleaned before drwaing process. For low carbon wire rod, we have patented descaling & brushing machine that will be sufficient for surface cleaning. For high carbon wire rod, we have fumeless pickling line to clean the rod surface efficiently. All of pretreatment devices can be installed either in-line with drawing machine or can be used separately.

Available options

Roller descaling & Brushing machine:

Sand belt descaler

Fumeless pickling line

Take-ups

Coiler: We could offer comprehensive series of dead block coiler for different sizes of wire. Our coilers are designed as sturdy structure and high working speed. We also have turntable for catch weight coils to meet customer’s requirements. The benefit of using a drawing dead block in the wire drawing process is to eliminate one block on the wire drawing machine. For coiling high carbon steel wire, the coiler is provided with die and capstan and equipped with own cooling system.

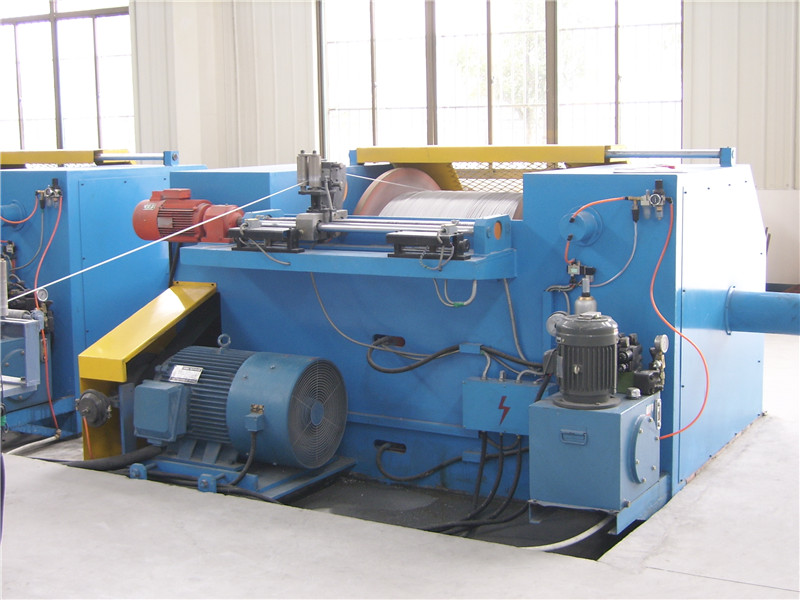

Spooler: Spoolers work in combination with steel wire drawing machines and are used to take up drawn wires on to rigid spools. We offer comprehensive series of spoolers for different drawn wire size. The spooler is driven by separate motor and the working speed can be synchronized with drawing machine

Other machines

Butt welder:

● High clamping force for wires

● Micro computer controlled for automatic welding&annealing process

● Easy adjustment of the jaws distance

● With grinding unit and cutting functions

● Annealing devices for both models are available

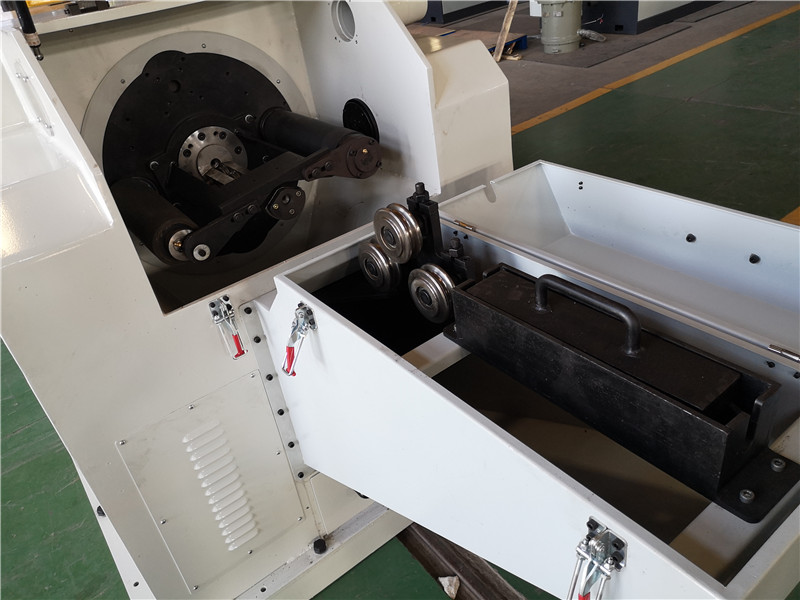

Wire pointer:

● Pull-in device to pre-feed wire rod within a drawing line

● Hardened rollers with long working life

● Movable machine body for easier operation

● Powerful motor driven for rollers

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for China Gold Supplier for Hot-Dip Steel Wire Galvanizing Line - Steel Wire Drawing Machine-Auxiliary Machines PengSheng , The product will supply to all over the world, such as: Turkmenistan, Peru, Malta, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.