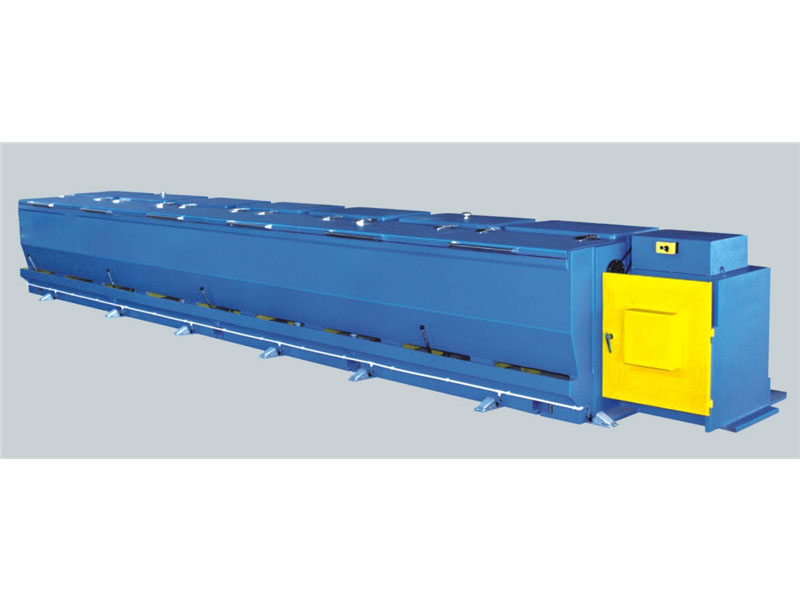

China wholesale Copper Rod Continuous Casting Machine - Copper/ Aluminum/ Alloy Rod Breakdown Machine PengSheng

China wholesale Copper Rod Continuous Casting Machine - Copper/ Aluminum/ Alloy Rod Breakdown Machine PengSheng Detail:

Productivity

• quick drawing die change system and two motor-driven for easy operation

• touchscreen display and control, high automatic operation

• single or double wire path design to meet different production requirements

Efficiency

•machine could be designed to produce copper as well as aluminum wire for investment saving.

•force cooling/ lubrication system and sufficient protection technology for transmission to guarantee machine with long service life

• meets different finished product diameters

Main technical data

| Type | DL400 | DLA400 | DLB400 |

| Material | Cu | Al/Al-Alloys | Brass (≥62/65) |

| Max inlet Ø [mm] | 8 | 9.5 | 8 |

| Outlet Ø range [mm] | 1.2-4.0 | 1.5-4.5 | 2.9-3.6 |

| No. of wires | 1/2 | 1/2 | 1 |

| No. of drafts | 7-13 | 7-13 | 9 |

| Max. speed [m/sec] | 25 | 25 | 7 |

| Wire elongation per draft | 26%-50% | 26%-50% | 18%-22% |

Product detail pictures:

Related Product Guide:

Our progress depends around the innovative machines, great talents and consistently strengthened technology forces for China wholesale Copper Rod Continuous Casting Machine - Copper/ Aluminum/ Alloy Rod Breakdown Machine PengSheng , The product will supply to all over the world, such as: Kyrgyzstan, Malta, azerbaijan, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

Write your message here and send it to us