China wholesale Rod Breakdown Line - Double Twist Bunching Machine PengSheng

China wholesale Rod Breakdown Line - Double Twist Bunching Machine PengSheng Detail:

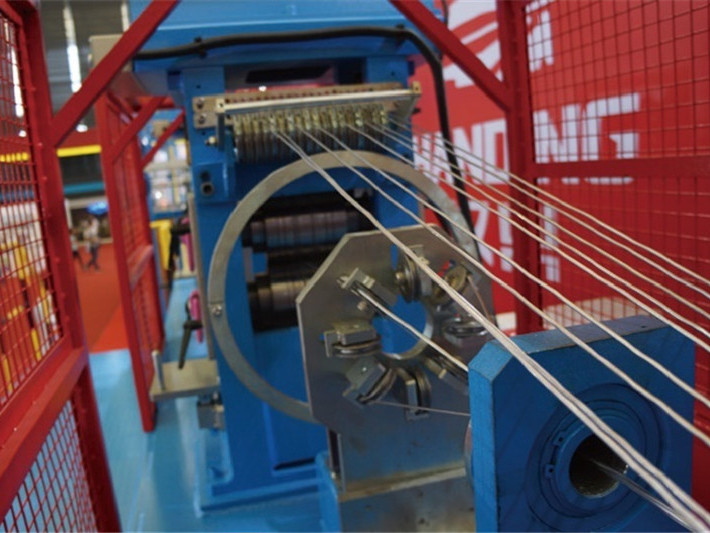

Double Twist Bunching Machine

For precision control and easy operation, AC technology, PLC & inverter control and HMI are applied in our double twist bunching machines. Meanwhile a variety of safety protection guarantee our machine running with high performance.

1. Double Twist Bunching Machine (Model: OPS-300D- OPS-800D)

Application: Main suitable for twisting above 7 strands of the silver jacketed wire, tinned wire, enameled wire, bare copper wire, copper-clad steel, copper cladding aluminum, etc. Left or right twisting direction can be selected freely.

| Model | OPS-300D | OPS-400D/ OPS -500D | OPS-630D | OPS-800D | OPS-800D |

| spool dia.(mm) | 300 | 400-500 | 630 | 800 | 1000 |

| max rotating speed (rpm) | 3000 | 3000 | 2000 | 2000 | 1500 |

| feeding wire dia. (mm) | 0.05-0.28 | 0.08- 0.45 | 0.12- 0.62 | 0.2-1.04 | 0.45-2.52 |

| twist cross section(mm²) | 0.035-0.45 | 0.035-2.5 | 0.18-6.0 | 0.8-16 | 6-35 |

| lay length(mm) | 10 Segment3.65-17.15 | 40 Segment6.3-50.4 | 34 Segment11.15-100 | 30 Segment20-160 | 34 Segment20-300 |

2, Double Twist Bunching Machine (Model: OPS-1250D – OPS -2500D)

Application: Main suitable for twisting copper wire, aluminum wire or PVC insulated wire below 7/19/37/61 strands to concentric twisting wire.

| Model | OPS-1250D | OPS -1600D | OPS -1800D | OPS -2000D | OPS -2240D | OPS -2500D |

| max. spool dia.(mm) | 1250 | 1600 | 1800 | 2000 | 2240 | 2500 |

| max. line speed(m/min) | 70-150 | 170-200 | 170-200 | 170-200 | 170-200 | 170-200 |

| max rotating speed (rpm) | 800 | 600 | 350 | 350 | 300 | 300 |

| feeding wire dia. (Al/Cu) (mm) | 1.0-3.0 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 |

| stand cross section(mm²) | 3.5-70 | 16-240 | 16-240 | 16-240 | 16-240 | 16-240 |

| compacting section (Cu) ( mm²) | 3.5-50 | 16-150 | 16-185 | 16-240 | 16-300 | 16-300 |

| compacting section (Al) ( mm²) | 3.5-70 | 16-240 | 16-240 | 16-300 | 16-400 | 16-400 |

| lay length(mm) | 40-350 | 40-350 | 50-600 | 60-600 | 60-600 | 60-600 |

| max. strand outer dia. (mm) | 15 | 25 | 35 | 35 | 35 | 35 |

Product detail pictures:

Related Product Guide:

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for China wholesale Rod Breakdown Line - Double Twist Bunching Machine PengSheng , The product will supply to all over the world, such as: Kenya, New York, Curacao, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

Write your message here and send it to us