China wholesale Rod Breakdown Line - High-Efficiency Wire and Cable Extruders PengSheng

China wholesale Rod Breakdown Line - High-Efficiency Wire and Cable Extruders PengSheng Detail:

Main characters

1, adopted excellent alloy while nitrogen treatment for screw and barrel, stable and long service life.

2, heating and cooling system is special designed while the temperature could be set in the range of 0-380℃ with high-precision control.

3, friendly operation by PLC+ touch screen

4, L/D ratio of 36:1 for special cable applications(physical foaming etc.)

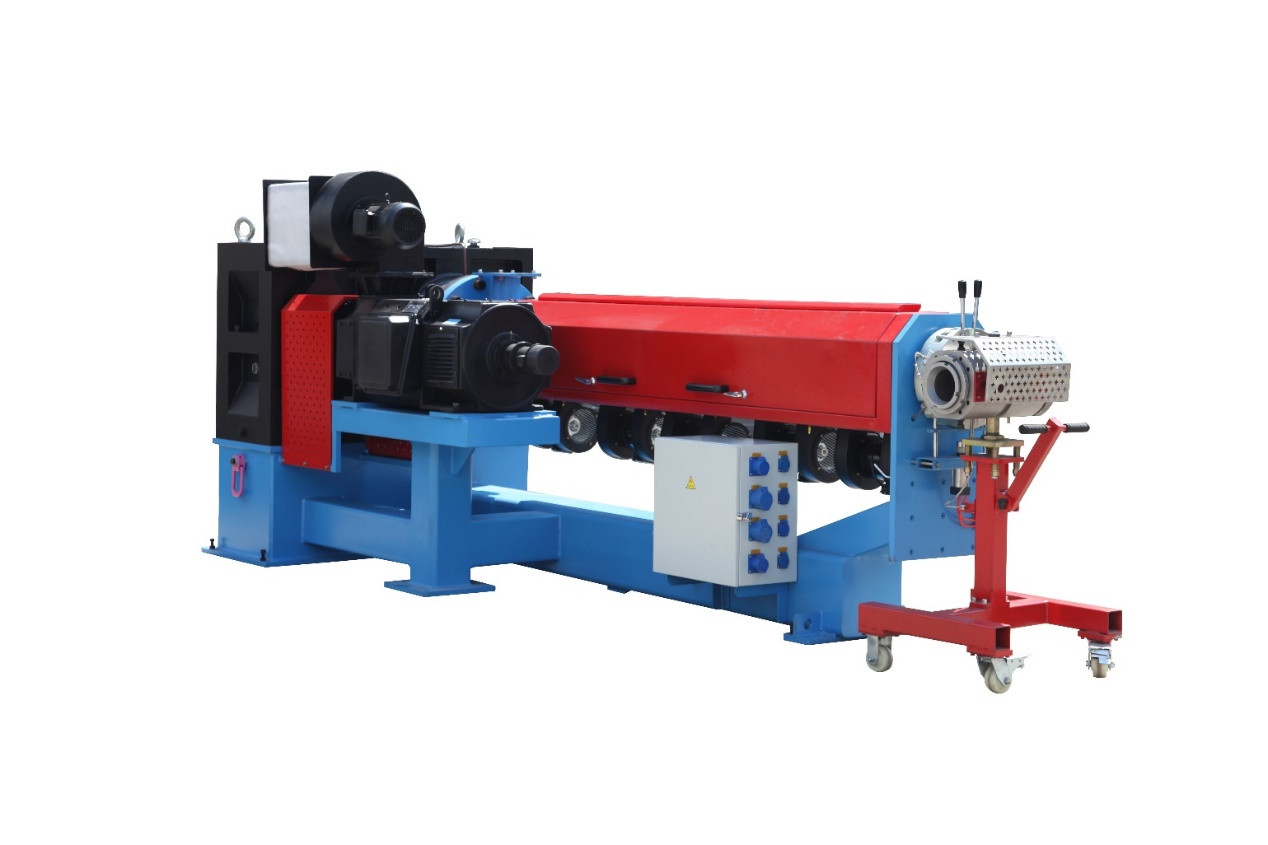

1.High efficiency extrusion machine

Application: Mainly used for insulation or sheath extrusion of wires and cables

| Model | Screw parameter | Extrusion capacity(kg/h) | Main Motor power(kw) | Outlet wire dia.(mm) | ||||

| Dia.(mm) | L/D ratio | Speed

(rpm) |

PVC | LDPE | LSHF | |||

| 30/25 | 30 | 25:1 | 20-120 | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 | 40 | 25:1 | 20-120 | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25:1 | 20-120 | 120 | 80 | 90 | 18.5 | 0.8-5 |

| 60/25 | 60 | 25:1 | 15-120 | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 | 70 | 25:1 | 15-120 | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 | 75 | 25:1 | 15-120 | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 | 80 | 25:1 | 10-120 | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 | 90 | 25:1 | 10-120 | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25:1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 | 120 | 25:1 | 5-90 | 800 | 470 | 540 | 132 | 8-80 |

| 150/25 | 150 | 25:1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 |

| 180/25 | 180 | 25:1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 |

| 200/25 | 200 | 25:1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 |

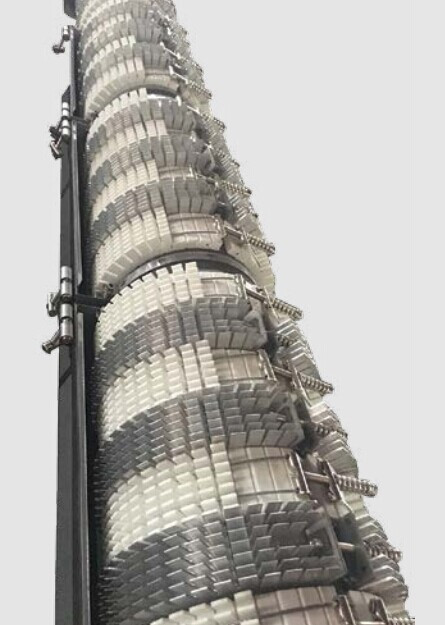

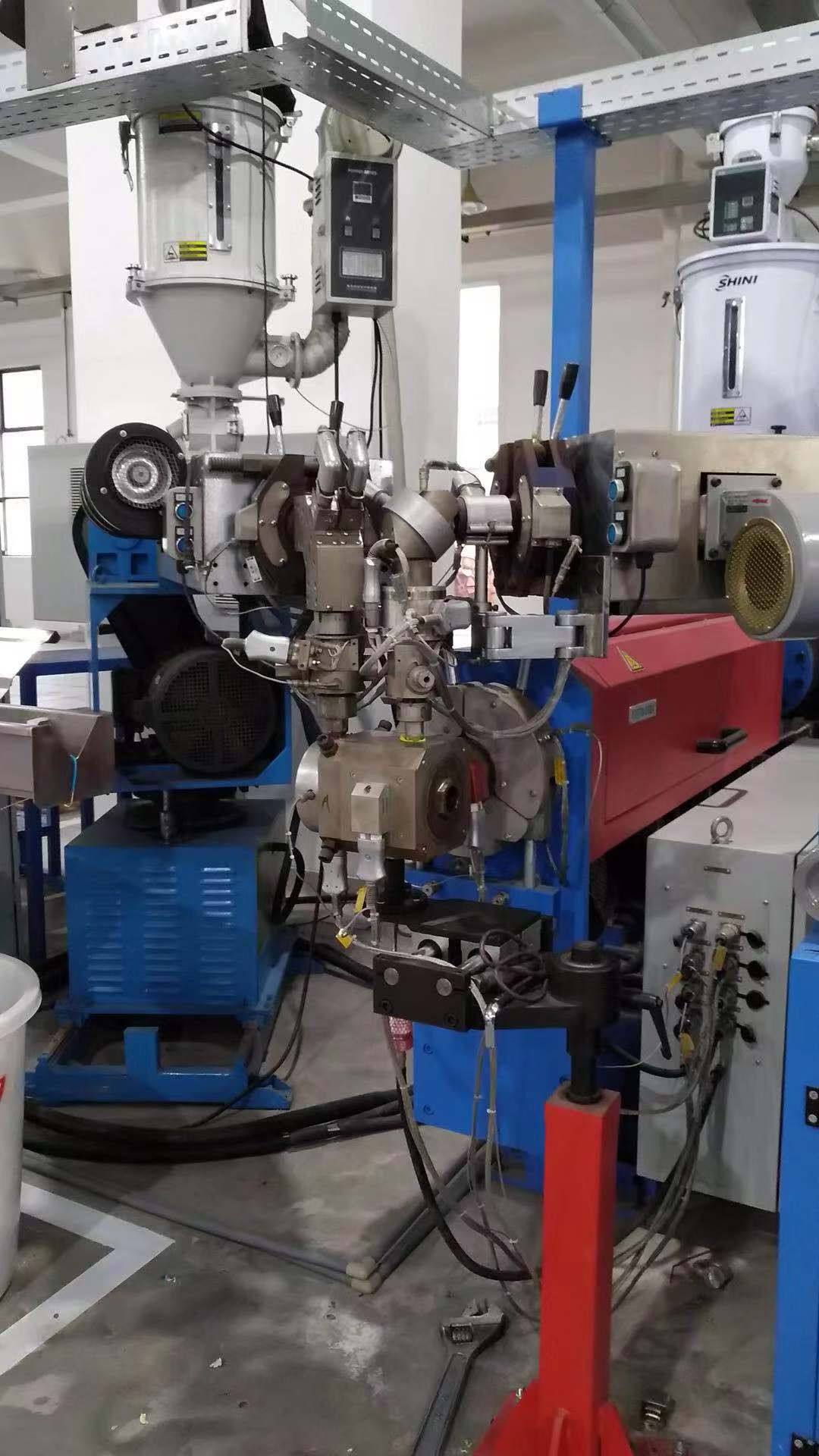

2.Double layer co-extrusion line

Application: Co-extrusion line is suitable for low smoke halogen free, XLPE extrusion, mainly used for production of nuclear power station cables, etc.

| Model | Screw parameter | Extrusion capacity (kg/h) | Inlet wire dia. (mm) | Outlet wire dia. (mm) | Line speed

(m/min) |

|

| Dia.(mm) | L/D ratio | |||||

| 50+35 | 50+35 | 25:1 | 70 | 0.6-4.0 | 1.0-4.5 | 500 |

| 60+35 | 60+35 | 25:1 | 100 | 0.8-8.0 | 1.0-10.0 | 500 |

| 65+40 | 65+40 | 25:1 | 120 | 0.8-10.0 | 1.0-12.0 | 500 |

| 70+40 | 70+40 | 25:1 | 150 | 1.5-12.0 | 2.0-16.0 | 500 |

| 80+50 | 80+50 | 25:1 | 200 | 2.0-20.0 | 4.0-25.0 | 450 |

| 90+50 | 90+50 | 25:1 | 250 | 3.0-25.0 | 6.0-35.0 | 400 |

3.Triple-extrusion line

Application: Triple-extrusion line is suitable for low smoke halogen free, XLPE extrusion, mainly used for production of nuclear power station cables, etc.

| Model | Screw parameter | Extrusion capacity (kg/h) | Inlet wire dia. (mm) | Line speed

(m/min) |

|

| Dia.(mm) | L/D ratio | ||||

| 65+40+35 | 65+40+35 | 25:1 | 120/40/30 | 0.8-10.0 | 500 |

| 70+40+35 | 70+40+35 | 25:1 | 180/40/30 | 1.5-12.0 | 500 |

| 80+50+40 | 80+50+40 | 25:1 | 250/40/30 | 2.0-20.0 | 450 |

| 90+50+40 | 90+50+40 | 25:1 | 350/100/40 | 3.0-25.0 | 400 |

Product detail pictures:

Related Product Guide:

We emphasize enhancement and introduce new solutions into the market just about every year for China wholesale Rod Breakdown Line - High-Efficiency Wire and Cable Extruders PengSheng , The product will supply to all over the world, such as: Oman, Armenia, Qatar, We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!