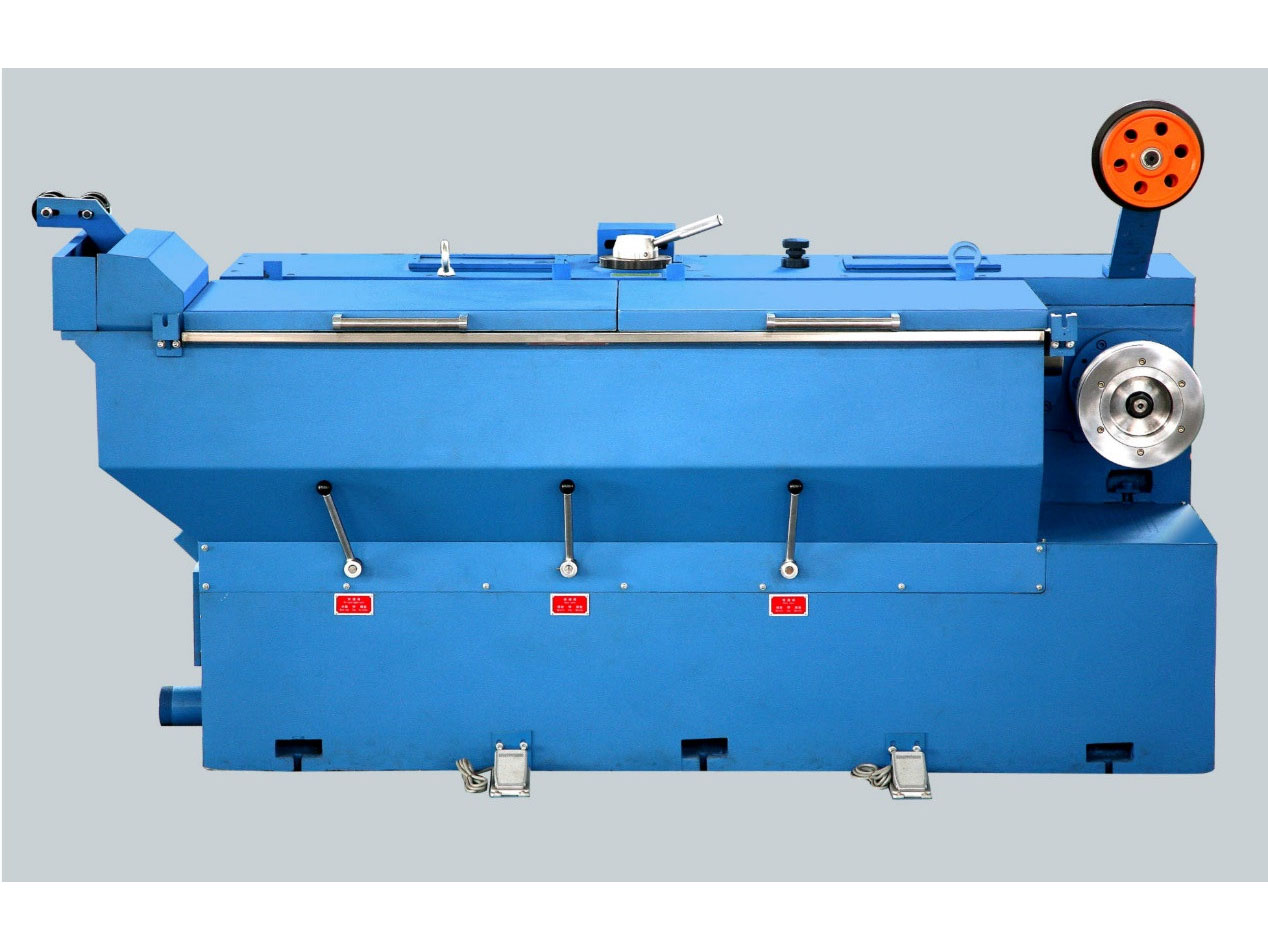

Chinese Professional Continuous Galvanizing Wire Line – High-Efficiency Intermediate Drawing Machine PengSheng

Chinese Professional Continuous Galvanizing Wire Line – High-Efficiency Intermediate Drawing Machine PengSheng Detail:

Productivity

• touchscreen display and control, high automatic operation

• single or double wire path design to meet different production requirements

Efficiency

• meets different finished product diameters

•force cooling/ lubrication system and sufficient protection technology for transmission to safeguard machine with long service life

Main technical data

| Type | ZL250-17 | ZL250B-17 | DZL250-17 | DZL250B-17 |

| Material | Cu | Al/Al-Alloys | Cu | Al/Al-Alloys |

| Max inlet Ø [mm] | 3.5 | 4.2 | 3.0 | 4.2 |

| Outlet Ø range [mm] | 0.32-2.76 | 0.4-2.76 | 0.4-2.0 | 0.4-2.0 |

| No. of wires | 1 | 1 | 2 | 2 |

| No. of drafts | 9/17 | 9/17 | 9/17 | 9/17 |

| Max. speed [m/sec] | 30 | 30 | 30 | 30 |

| Wire elongation per draft | 18%-25% | 13%-18% | 18%-25% | 13%-18% |

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Chinese Professional Continuous Galvanizing Wire Line – High-Efficiency Intermediate Drawing Machine PengSheng , The product will supply to all over the world, such as: Thailand, Japan, Surabaya, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

Write your message here and send it to us