Chinese wholesale Steel Strip Welding Wire Line - Flux Cored Welding Wire Production Line PengSheng

Chinese wholesale Steel Strip Welding Wire Line - Flux Cored Welding Wire Production Line PengSheng Detail:

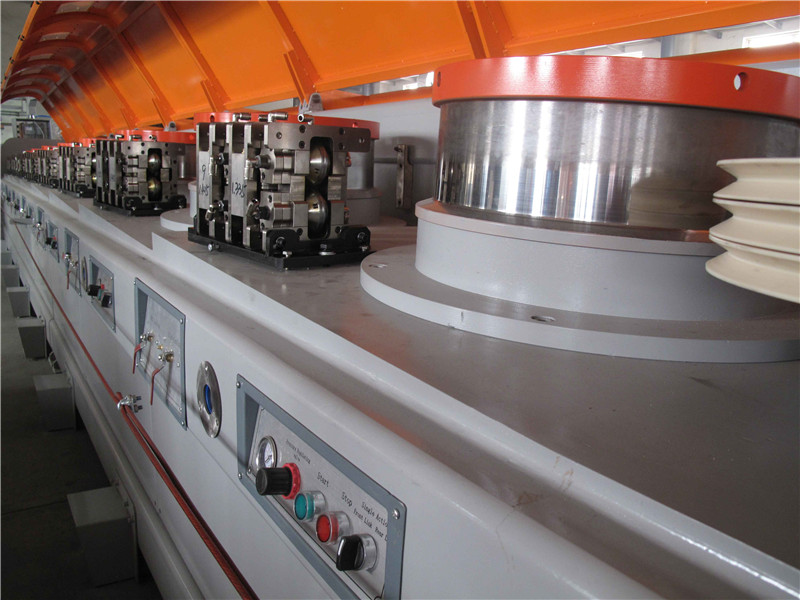

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

● Forming machine with powder feeding system

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for Chinese wholesale Steel Strip Welding Wire Line - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: Argentina, Kazakhstan, Kenya, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

Write your message here and send it to us