Chinese wholesale Steel Strip Welding Wire Line - Flux Cored Welding Wire Production Line PengSheng

Chinese wholesale Steel Strip Welding Wire Line - Flux Cored Welding Wire Production Line PengSheng Detail:

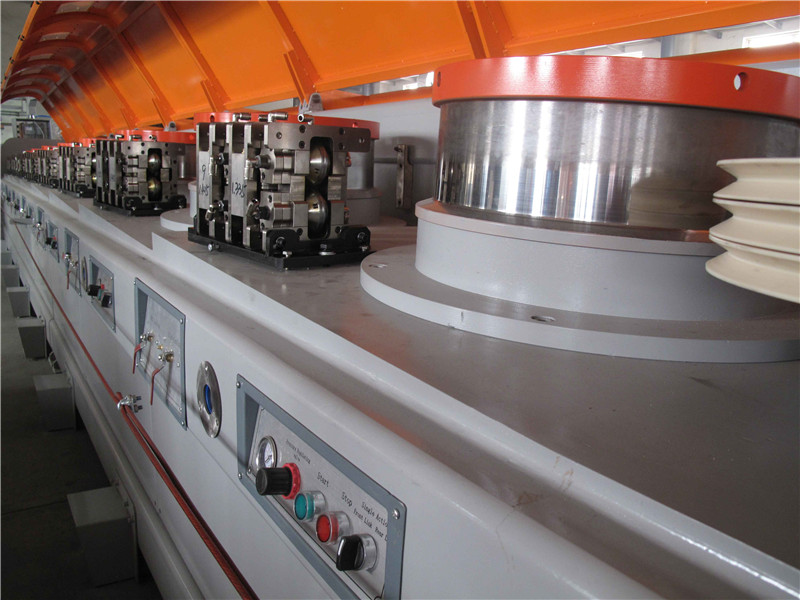

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

● Forming machine with powder feeding system

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for Chinese wholesale Steel Strip Welding Wire Line - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: moldova, Uzbekistan, Lithuania, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

Write your message here and send it to us