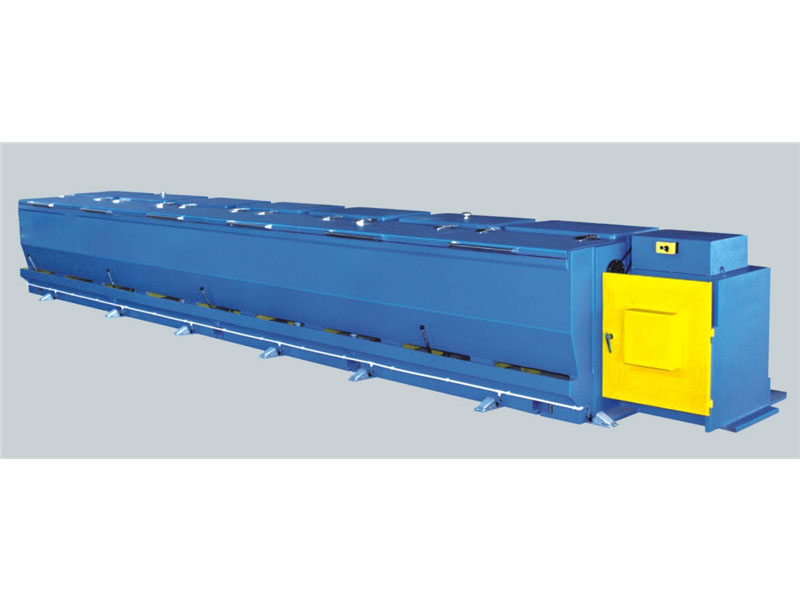

Copper/ Aluminum/ Alloy Rod Breakdown Machine

Productivity

• quick drawing die change system and two motor-driven for easy operation

• touchscreen display and control, high automatic operation

• single or double wire path design to meet different production requirements

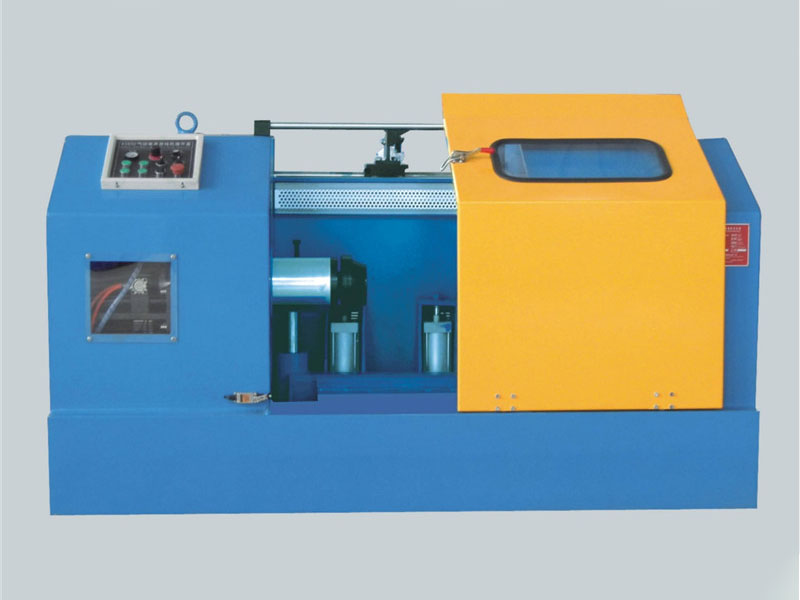

Efficiency

•machine could be designed to produce copper as well as aluminum wire for investment saving.

•force cooling/ lubrication system and sufficient protection technology for transmission to guarantee machine with long service life

• meets different finished product diameters

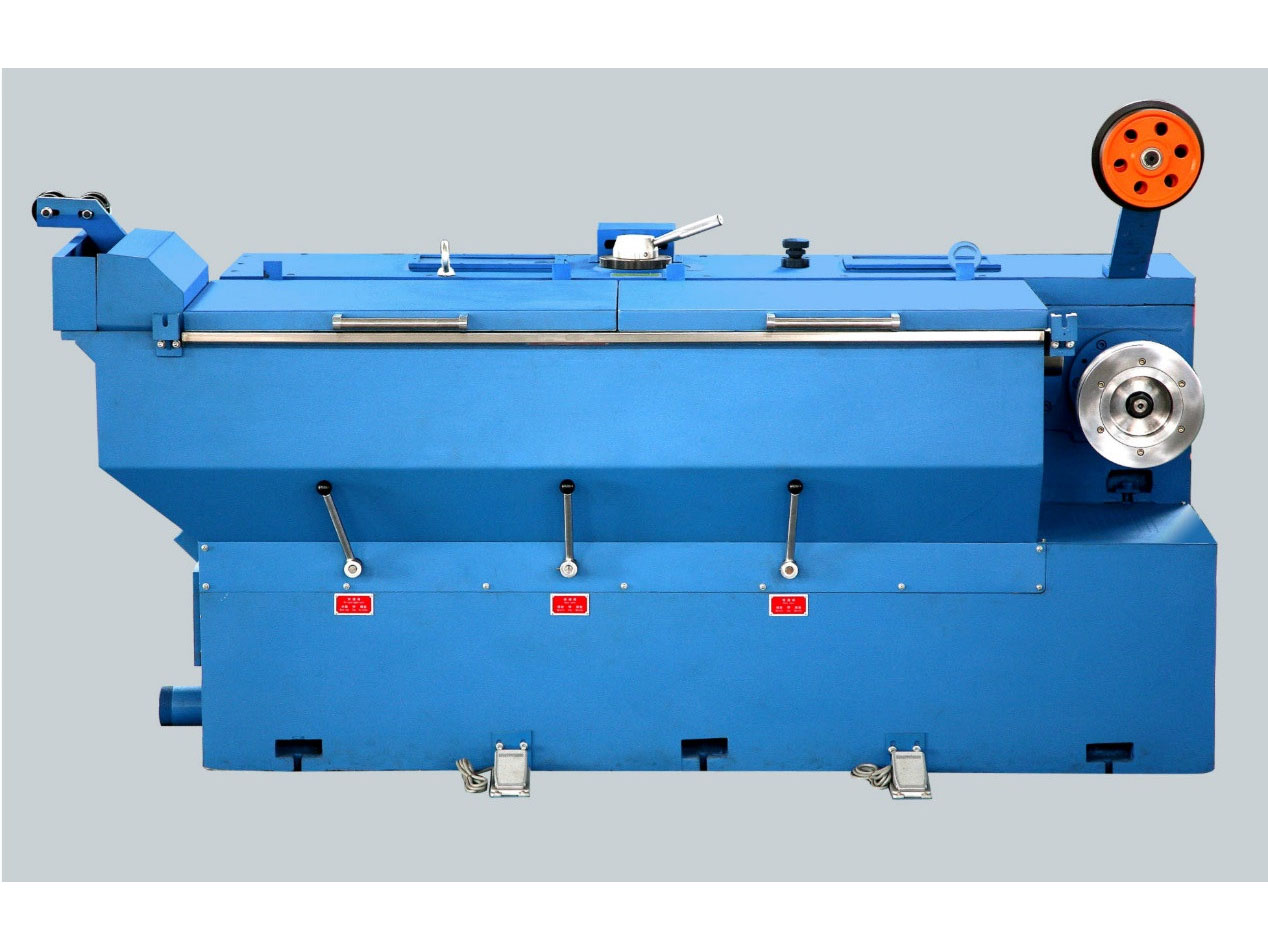

Main technical data

| Type | DL400 | DLA400 | DLB400 |

| Material | Cu | Al/Al-Alloys | Brass (≥62/65) |

| Max inlet Ø [mm] | 8 | 9.5 | 8 |

| Outlet Ø range [mm] | 1.2-4.0 | 1.5-4.5 | 2.9-3.6 |

| No. of wires | 1/2 | 1/2 | 1 |

| No. of drafts | 7-13 | 7-13 | 9 |

| Max. speed [m/sec] | 25 | 25 | 7 |

| Wire elongation per draft | 26%-50% | 26%-50% | 18%-22% |

Write your message here and send it to us