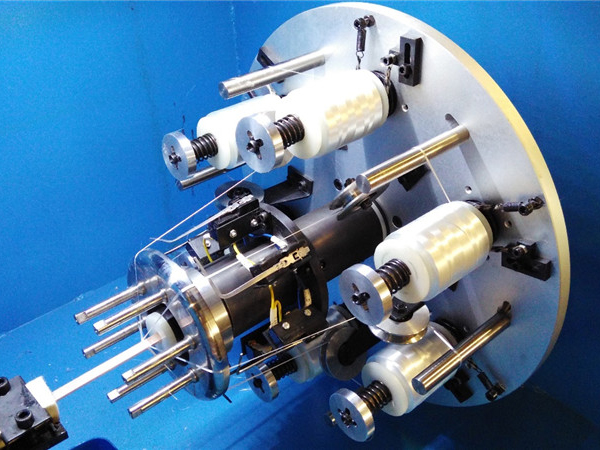

Douglas Fiberglass Taping Machine for Wire Insulating

Introduction

In the ever-evolving landscape of manufacturing, the Douglas Fiberglass Taping and Sintering Machine stands out as a pivotal innovation, particularly in the wire and cable insulating sector. This advanced machinery creates a seamless solution for high-quality insulation processes.

In conclusion, the Douglas Fiberglass Taping and Sintering Machine with high frequency inductor represents a significant advancement in the field of wire and cable insulating. By merging the capabilities of the Douglas Fiberglass Taping Machine and the Douglas Insulating Machine, it offers a comprehensive solution that meets the demands of modern manufacturing, ensuring efficiency, quality, and reliability in every application.

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 4 mm²—80 mm²(Width: 4mm-16mm, Thickness: 1.0mm-6.0mm)

Rotating speed: max. 1200 rpm

Line speed: max. 12 m/min.

Special Characteristics

Servo drive for the winding head

Automatic stop when fiber broken by laser sensor detection

IGBT induction heater and moving radiant oven

PLC control and touch screen operation