Drawing Machine for Copper,Aluminum and Alloy

-

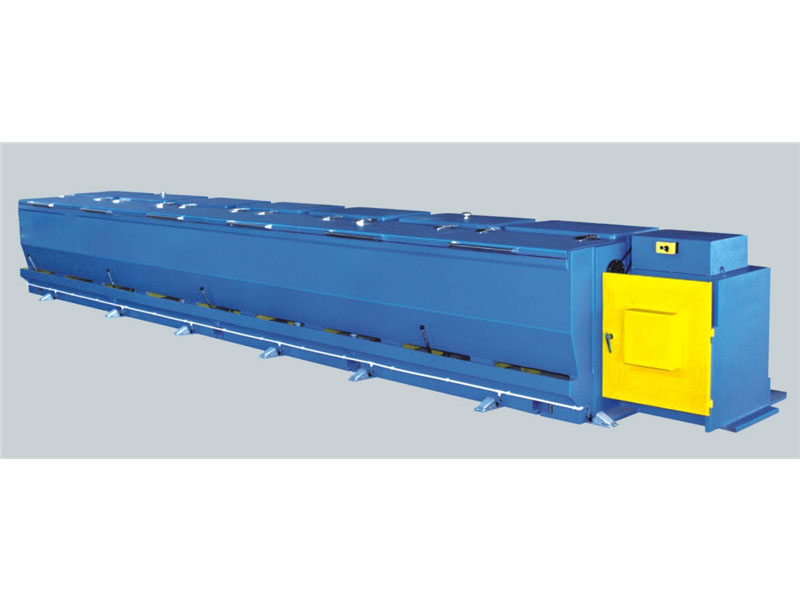

Rod Breakdown Machine with Individual Drives

• horizontal tandem design

• individual servo drive and control system

• Siemens reducer

• fully submerged cooling/emulsion system for long service life -

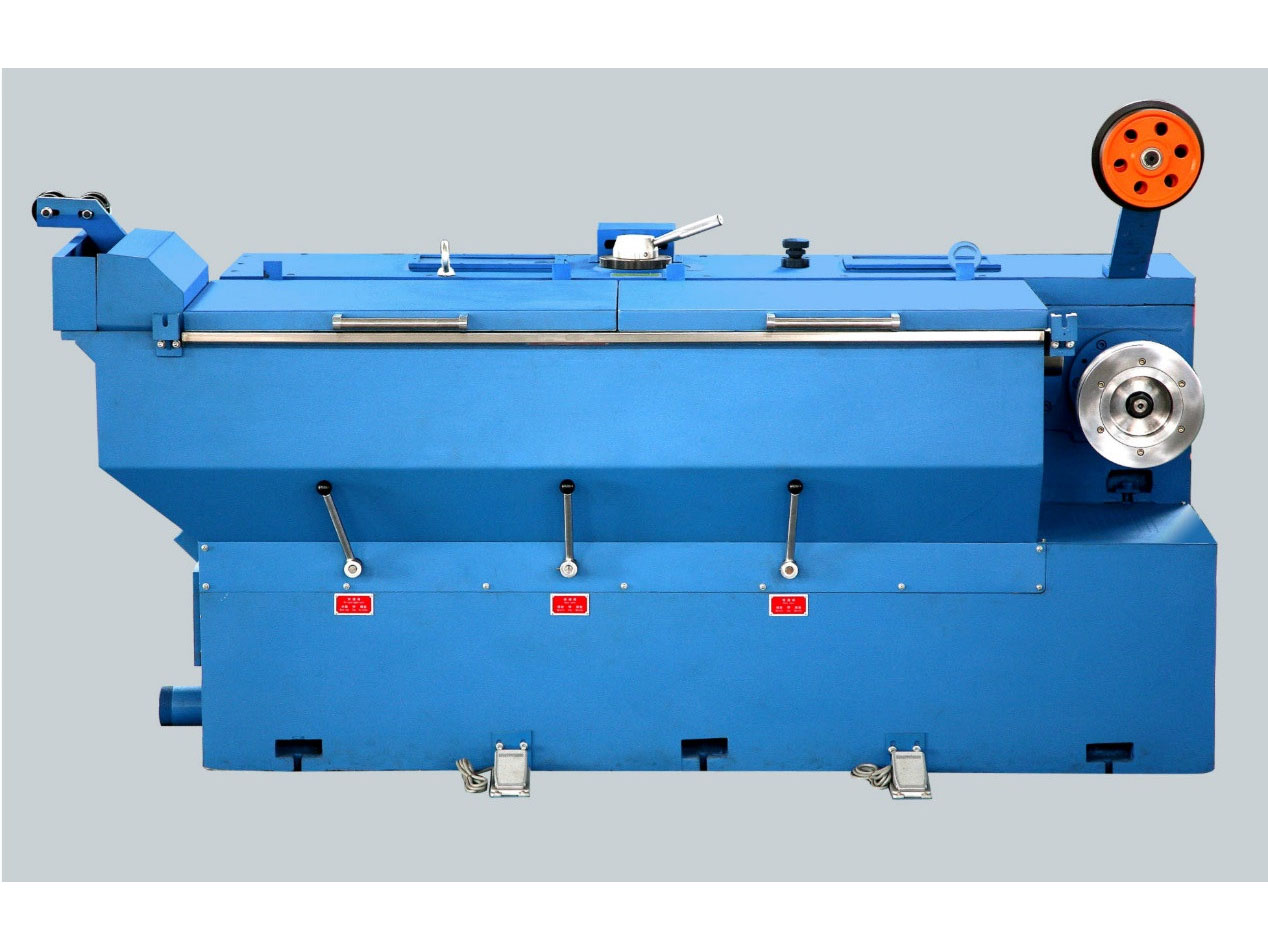

Copper/ Aluminum/ Alloy Rod Breakdown Machine

• horizontal tandem design

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear made by 20CrMoTi material.

• fully submerged cooling/emulsion system for long service life

• mechanical seal design (it is composed of water dumping pan, oil dumping ring and labyrinth gland) to safeguard separation of drawing emulsion and gear oil. -

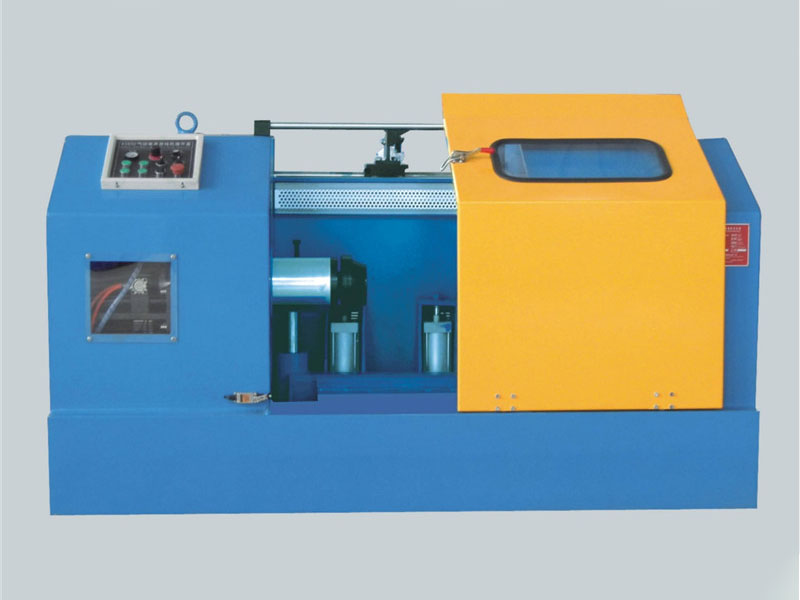

High-Efficiency Multi Wire Drawing Line

• compact design and reduced footprint

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear and shaft made by 8Cr2Ni4WA material.

• mechanical seal design (it is composed of water dumping pan, oil dumping ring and labyrinth gland) to safeguard separation of drawing emulsion and gear oil. -

High-Efficiency Intermediate Drawing Machine

• cone pulley type design

• force cooling/ lubrication to cycle gear oil of transmission

• helical precision gear made by 20CrMoTi material.

• fully submerged cooling/emulsion system for long service life

• mechanical seal design to safeguard separation of drawing emulsion and gear oil. -

High-Efficiency Fine Wire Drawing Machine

Fine Wire Drawing Machine • transmitted by high quality flat belts, low noise. • double converter drive, constant tension control, energy saving • traverse by ball scre Type BD22/B16 B22 B24 Max inlet Ø [mm] 1.6 1.2 1.2 Outlet Ø range [mm] 0.15-0.6 0.1-0.32 0.08-0.32 No. of wires 1 1 1 No. of drafts 22/16 22 24 Max. speed [m/sec] 40 40 40 Wire elongation per draft 15%-18% 15%-18% 8%-13% Fine Wire Drawing Machine with High-Capacity Spooler • compact design for space saving •... -

Horizontal DC Resistance Annealer

• horizontal DC resistance annealer is suitable for rod breakdown machines and intermediate drawing machines

• digital annealing voltage control for wire with consistent quality

• 2-3 zone annealing system

• nitrogen or steam protection system for preventing oxidization

• ergonomic and user-friendly machine design for easy maintenance -

Vertical DC Resistance Annealer

• vertical DC resistance annealer for intermediate drawing machines

• digital annealing voltage control for wire with consistent quality

• 3-zone annealing system

• nitrogen or steam protection system for preventing oxidization

• ergonomic and user-friendly design for easy maintenance -

High Quality Coiler/Barrel Coiler

• easy for use in the rod breakdown machine and intermediate drawing machine line

• suitable for barrels and cardboard barrels

• eccentric rotating unit design for coiling wire with rosette pattern laying, and trouble-free downstream processing -

Automatic Double Spooler with Fully Automatic Spool Changing System

• double spooler design and fully automatic spool changing system for continuous operation

• three-phase AC drive system and individual motor for wire traversing

• adjustable pintle-type spooler, wide range of spool size could be used -

Compact Design Dynamic Single Spooler

• compact design

• adjustable pintle-type spooler, wide range of spool size could be used

• double spool lock structure for spool running safety

• traverse controlled by inverter -

Single Spooler in Portal Design

• specially designed for compact wire winding, suitable for equipping in rod breakdown machine or rewinding line

• individual touch screen and PLC system

• hydraulic control design for spool loading and clamping