Factory Cheap Hot Hot Dip Galvanized Wire Plant - Double Twist Bunching Machine PengSheng

Factory Cheap Hot Hot Dip Galvanized Wire Plant - Double Twist Bunching Machine PengSheng Detail:

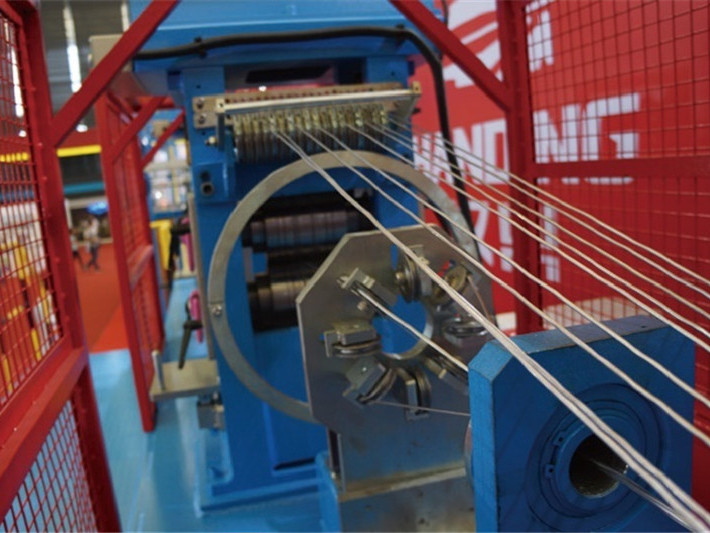

Double Twist Bunching Machine

For precision control and easy operation, AC technology, PLC & inverter control and HMI are applied in our double twist bunching machines. Meanwhile a variety of safety protection guarantee our machine running with high performance.

1. Double Twist Bunching Machine (Model: OPS-300D- OPS-800D)

Application: Main suitable for twisting above 7 strands of the silver jacketed wire, tinned wire, enameled wire, bare copper wire, copper-clad steel, copper cladding aluminum, etc. Left or right twisting direction can be selected freely.

| Model | OPS-300D | OPS-400D/ OPS -500D | OPS-630D | OPS-800D | OPS-800D |

| spool dia.(mm) | 300 | 400-500 | 630 | 800 | 1000 |

| max rotating speed (rpm) | 3000 | 3000 | 2000 | 2000 | 1500 |

| feeding wire dia. (mm) | 0.05-0.28 | 0.08- 0.45 | 0.12- 0.62 | 0.2-1.04 | 0.45-2.52 |

| twist cross section(mm²) | 0.035-0.45 | 0.035-2.5 | 0.18-6.0 | 0.8-16 | 6-35 |

| lay length(mm) | 10 Segment3.65-17.15 | 40 Segment6.3-50.4 | 34 Segment11.15-100 | 30 Segment20-160 | 34 Segment20-300 |

2, Double Twist Bunching Machine (Model: OPS-1250D – OPS -2500D)

Application: Main suitable for twisting copper wire, aluminum wire or PVC insulated wire below 7/19/37/61 strands to concentric twisting wire.

| Model | OPS-1250D | OPS -1600D | OPS -1800D | OPS -2000D | OPS -2240D | OPS -2500D |

| max. spool dia.(mm) | 1250 | 1600 | 1800 | 2000 | 2240 | 2500 |

| max. line speed(m/min) | 70-150 | 170-200 | 170-200 | 170-200 | 170-200 | 170-200 |

| max rotating speed (rpm) | 800 | 600 | 350 | 350 | 300 | 300 |

| feeding wire dia. (Al/Cu) (mm) | 1.0-3.0 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 |

| stand cross section(mm²) | 3.5-70 | 16-240 | 16-240 | 16-240 | 16-240 | 16-240 |

| compacting section (Cu) ( mm²) | 3.5-50 | 16-150 | 16-185 | 16-240 | 16-300 | 16-300 |

| compacting section (Al) ( mm²) | 3.5-70 | 16-240 | 16-240 | 16-300 | 16-400 | 16-400 |

| lay length(mm) | 40-350 | 40-350 | 50-600 | 60-600 | 60-600 | 60-600 |

| max. strand outer dia. (mm) | 15 | 25 | 35 | 35 | 35 | 35 |

Product detail pictures:

Related Product Guide:

continue on to further improve, to make sure product top quality in line with market and consumer standard requirements. Our firm has a excellent assurance program have already been established for Factory Cheap Hot Hot Dip Galvanized Wire Plant - Double Twist Bunching Machine PengSheng , The product will supply to all over the world, such as: kazakhstan, Czech, azerbaijan, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Write your message here and send it to us