Factory Cheap Hot Hot Dip Galvanized Wire Plant - Wire and Cable Laser Marking Machine PengSheng

Factory Cheap Hot Hot Dip Galvanized Wire Plant - Wire and Cable Laser Marking Machine PengSheng Detail:

Working Principle

The laser marking device detects the pipeline speed of the pipe by the speed measuring device, and the marking machine realizes dynamic marking according to the pulse change marking speed fed back by the encoder.The interval marking function such as wire rod industry and software implementation, etc., can be set by software parameter setting. There is no need for photoelectric detection switch for flight marking equipment in wire rod industry. after one trigger, the software automatically realizes multiple marking at equal intervals.

U Series-Ultra Violet (UV) Laser Source

| HRU Series | |||

| Applicable Material & Color | Most of the material & colorPVC, PE, XLPE, TPE, LSZH, PV, PTFE, YGC, Silicone Rubber etc,. | ||

| Model | HRU-350TL | HRU-360ML | HRU-400ML |

| Marking Speed(M/min) | 80m/min | 100m/min | 150m/min |

| Compatibility (General mark speed based on content) |

400m/min(Wire number ) | 500m/min(Wire number ) | |

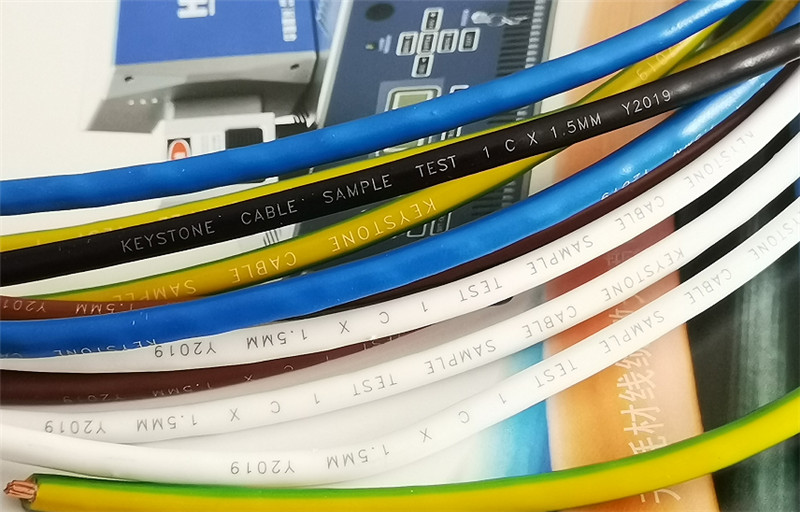

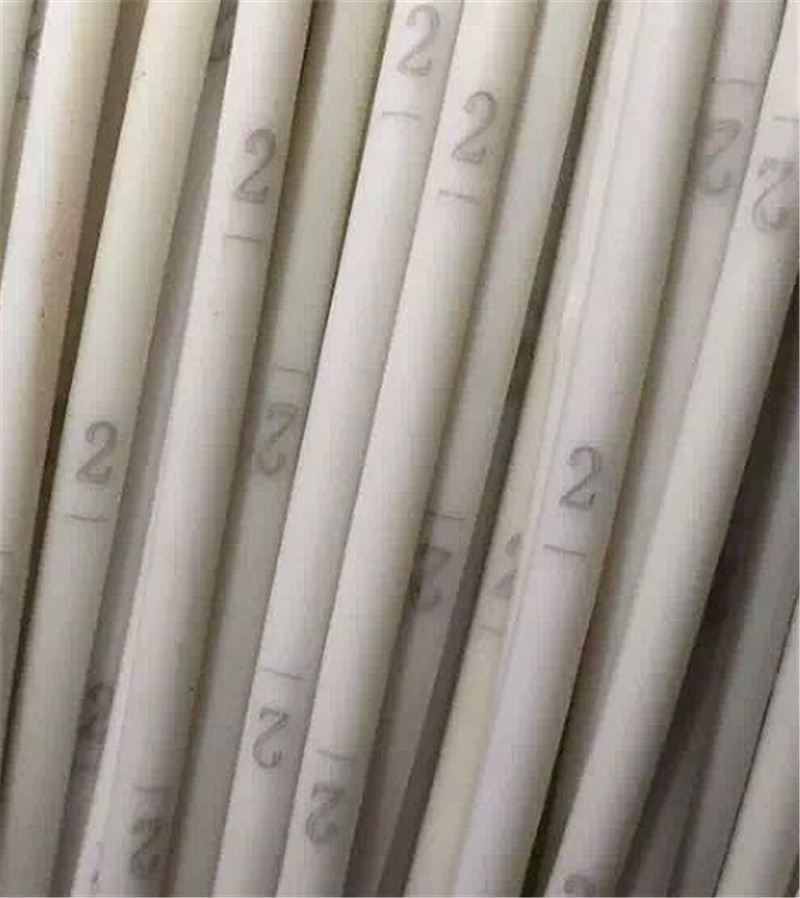

U Series Marking Effect

G Series -Fiber Laser Source

| HRG Series | ||||

| Applicable Material & Color | Black insulator sheath, BTTZ/YTTW. PVC,PE,LSZH,PV,PTFE,XLPE.Aluminum.Alloy.Metal.Acrylics, etc,. | |||

| Model | HRG-300L | HRG-500L | HRG-300M | HRG-500M |

| Marking Speed(M/min) | 80m/min | 120m/min | 100m/min | 150m/min |

| Compatibility(General mark speed based on content) | 400m/min (Wire number ) |

500m/min(Wire number ) | ||

G Series Marking Effect

C Series- Carbon Dioxide (Co2) Laser Source

| HRC Series | |||

| Applicable Material & Color | PVC (Various color), LSZH (Orange/Red), PV (Red), TPE (Orange), Rubber etc,. | ||

| Model | HRC-300M | HRC-600M | HRC-800M |

| Marking Speed(M/min) | 70m/min | 110m/min | 150m/min |

C Series Marking Effect

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Factory Cheap Hot Hot Dip Galvanized Wire Plant - Wire and Cable Laser Marking Machine PengSheng , The product will supply to all over the world, such as: Albania, Tajikistan, Johor, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.

Write your message here and send it to us