Factory Cheap Hot Magnetic Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng

Factory Cheap Hot Magnetic Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng Detail:

Main technical data

Conductor area: 5 mm²—120mm²(or customized)

Covering layer: 2 or 4 times of layers

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

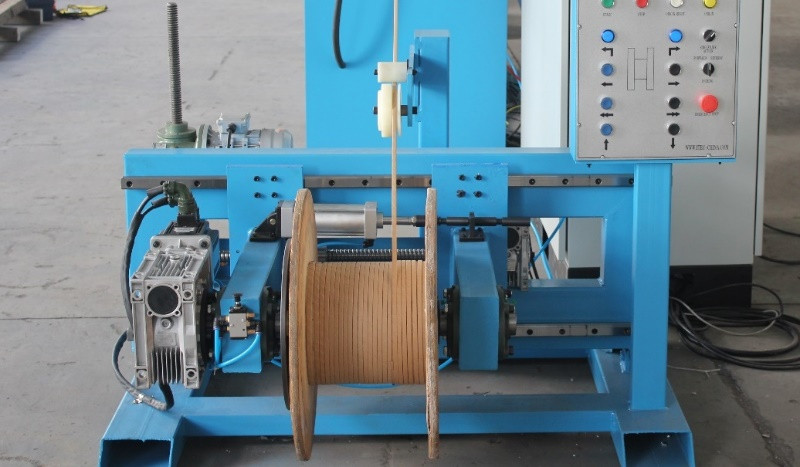

Taping head

Caterpillar

Take-up

Product detail pictures:

Related Product Guide:

High quality Very first,and Shopper Supreme is our guideline to offer the most beneficial company to our clients.Nowadays, we're hoping our best to be certainly one of the top exporters in our area to satisfy consumers additional will need for Factory Cheap Hot Magnetic Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng , The product will supply to all over the world, such as: Benin, Philippines, Detroit, If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Remember to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

Write your message here and send it to us