Featured

-

Fixed Competitive Price Paper Taping Machine - Continuous Cladding Machinery PengSheng

Principle The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die t... -

Best Price on Steel Strand Productio Line - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

Hot New Products Aluminum Clad Steel Wire Continuous Cladding Machine - High-Efficiency Fine Wire Drawing Machine PengSheng

Fine Wire Drawing Machine • transmitted by high quality flat belts, low noise. • double converter drive, constant tension control, energy saving • traverse by ball scre Type BD22/B16 B22 B24 Max inlet Ø [mm] 1.6 1.2 1.2 Outlet Ø range [mm] 0.15-0.6 0.1-0.32 0.08-0.32 No. of wires 1 1 1 No. of drafts 22/16 22 24 Max. speed [m/sec] 40 40 40 Wire elongation per draft 15%-18% 15%-18% 8%-13% Fine Wire Drawing Machine with High-Capacity Spooler • compact design for space saving •... -

2022 wholesale price Copper Casting Machine - Up Casting system of Cu-OF Rod PengSheng

Raw material Good quality copper cathode is suggested to be the raw material for the production to ensure the high mechanical and electrical quality product. Some percentage of recycled copper could be used too. The de-oxygen time in the furnace will be longer and that may shorter the working life of the furnace. A separte melting furnace for the copper scrap could be installed before the melting furnace to use full recycled copper. Furnace Bricks and sand built with melting channels, the fur... -

New Delivery for Double Twist Bunching Machine - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

2022 Good Quality Wire Fiberglass Insulating Machine - PI Film/Kapton® Taping Machine PengSheng

Main technical data Round conductor diameter: 2.5mm—6.0mm Flat conductor area: 5 mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm) Rotating speed: max. 1500 rpm Line speed: max. 12 m/min Special Characteristics -Servo drive for the concentric tapping head -IGBT induction heater and moving radiant oven -Auto-stop when film broken -PLC control and touch screen operation Overview Taping IGBT Induction heater Radiant oven Take-up Product -

New Arrival China Glass Fiber Insulating Machine For Wire - Combined Taping Machine – Multi Conductors PengSheng

Main technical data Single wire quantity: 2/3/4 (or customized) Single wire area: 5 mm²—80mm² Rotating speed: max. 1000 rpm Line speed: max. 30 m/min. Pitch accuracy: ±0.05 mm Taping pitch: 4~40 mm, step less adjustable Special Characteristics -Servo drive for the taping head -Rigid and modular structure design to eliminate vibration interaction -Taping pitch and speed easy adjusted by touch screen -PLC control and touch screen operation Overview Taping Caterpillar Take-up -

Cheapest Price Steel Wire Strander - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

High Quality Electromagnetic Wire Taping Machine - Combined Taping Machine – Multi Conductors PengSheng

Main technical data Single wire quantity: 2/3/4 (or customized) Single wire area: 5 mm²—80mm² Rotating speed: max. 1000 rpm Line speed: max. 30 m/min. Pitch accuracy: ±0.05 mm Taping pitch: 4~40 mm, step less adjustable Special Characteristics -Servo drive for the taping head -Rigid and modular structure design to eliminate vibration interaction -Taping pitch and speed easy adjusted by touch screen -PLC control and touch screen operation Overview Taping Caterpillar Take-up -

China Cheap price Upcasting Machine - Copper continuous casting and rolling line—copper CCR line PengSheng

Raw material and furnace By using vertical melting furnace and titled holding furnace, you can feed copper cathode as the raw material and then produce copper rod with the highest constant quality and continuous&high production rate. By using reverberatory furnace, you can feed 100% copper scrap in various quality and purity. The furnace standard capacity is 40, 60, 80 and 100 tons loading per shift/day. The furnace is developed with: -Increased thermal efficiency -Long working life -Easi... -

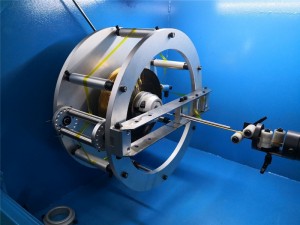

Factory Cheap Hot Magnetic Wire Paper Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng

Main technical data Conductor area: 5 mm²—120mm²(or customized) Covering layer: 2 or 4 times of layers Rotating speed: max. 1000 rpm Line speed: max. 30 m/min. Pitch accuracy: ±0.05 mm Taping pitch: 4~40 mm, step less adjustable Special Characteristics -Servo drive for the taping head -Rigid and modular structure design to eliminate vibration interaction -Taping pitch and speed easy adjusted by touch screen -PLC control and touch screen operation Overview Taping head Caterpillar Take-up -

Factory Cheap Hot Scrap Copper Casting Machine - Up Casting system of Cu-OF Rod PengSheng

Raw material Good quality copper cathode is suggested to be the raw material for the production to ensure the high mechanical and electrical quality product. Some percentage of recycled copper could be used too. The de-oxygen time in the furnace will be longer and that may shorter the working life of the furnace. A separte melting furnace for the copper scrap could be installed before the melting furnace to use full recycled copper. Furnace Bricks and sand built with melting channels, the fur...