Featured

-

OEM Supply Multiwire Drawing Lines - Continuous Cladding Machinery PengSheng

Principle The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die t... -

Manufactur standard Copper Extrusion Machine - Continuous Cladding Machinery PengSheng

Principle The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die t... -

Factory Supply Prestressed Steel Wire Stranding Line - Steel Wire & Rope Closing Line PengSheng

Main technical data No. Model Number of bobbin Rope size Rotating Speed (rpm) Tension wheel size (mm) Motor power (KW) Min. Max. 1 KS 6/630 6 15 25 80 1200 37 2 KS 6/800 6 20 35 60 1600 45 3 KS 8/1000 8 25 50 50 1800 75 4 KS 8/1600 8 50 100 35 3000 90 5 KS 8/1800 8 60 120 30 4000 132 6 KS 8/2000 8 70 150 25 5000 160 -

Factory Promotional Drawn Steel Wire Machine - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

Quality Inspection for Single Twist Bunching Machine - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

Factory wholesale PC Strand Production Line - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

OEM/ODM Manufacturer Brass Rod Drawing Machine - Continuous Cladding Machinery PengSheng

Principle The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die t... -

Factory Promotional Drawn Steel Wire Machine - Continuous Extrusion Machinery PengSheng

Advantages 1, plastic deformation of feeding rod under the friction force and high temperature which eliminates the internal defects in the rod itself completely to ensure the final products with excellent product performance and high dimensional accuracy. 2, neither preheating nor annealing, good quality products gained by extrusion process with lower power consumption. 3, with a single size rod feeding, the machine could produce a wide size range of products by using different dies. 4, the... -

Best Price on Under Roller Type Steel Rope Strandign Machine - Steel Wire Hot-Dip Galvanizing Line PengSheng

Galvanized wire products ● Low carbon bedding spring wire ● ACSR (Aluminum conductor steel reinforced) ● Armoring cables ● Razor wires ● Baling wires ● Some general purpose galvanized strand ● Galvanized wire mesh & fence Main features ● High efficiency heating unit and insulation ● Matal or ceramic pot for zinc ● Immersion type burners with full-auto N2 wiping system ● Fumes energy reused on the dryer and zinc pan ● Networked PLC control system Item Specification Inlet wire ma... -

Quality Inspection for Single Twist Bunching Machine - Continuous Cladding Machinery PengSheng

Principle The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die t... -

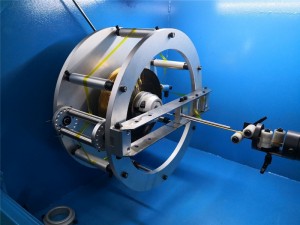

Wholesale Price China Magnet Wire Paper Taping Machine - PI Film/Kapton® Taping Machine PengSheng

Main technical data Round conductor diameter: 2.5mm—6.0mm Flat conductor area: 5 mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm) Rotating speed: max. 1500 rpm Line speed: max. 12 m/min Special Characteristics -Servo drive for the concentric tapping head -IGBT induction heater and moving radiant oven -Auto-stop when film broken -PLC control and touch screen operation Overview Taping IGBT Induction heater Radiant oven Take-up Product -

18 Years Factory Hot-Dip Steel Wire Galvanizing Line - Steel Wire & Rope Tubular Stranding Line PengSheng

Main features ● High speed rotor system with international brand bearings ● Stable runinng of wire stranding process ● High quality seamless steel pipe for stranding tube with tempering treatment ● Optional for the preformer, post former and compacting equipment ● Double capstan haul-offs tailored to the customer requirements Main technical data No. Model Wire Size(mm) Strand Size(mm) Power (KW) Rotating Speed(rpm) Dimension (mm) Min. Max. Min. Max. 1 6/200 0...