Good Quality Copper Rod Upcast - Double Twist Bunching Machine PengSheng

Good Quality Copper Rod Upcast - Double Twist Bunching Machine PengSheng Detail:

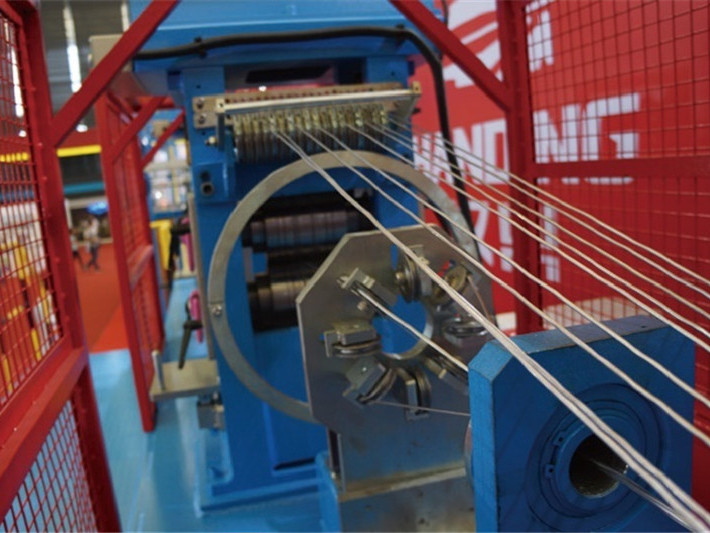

Double Twist Bunching Machine

For precision control and easy operation, AC technology, PLC & inverter control and HMI are applied in our double twist bunching machines. Meanwhile a variety of safety protection guarantee our machine running with high performance.

1. Double Twist Bunching Machine (Model: OPS-300D- OPS-800D)

Application: Main suitable for twisting above 7 strands of the silver jacketed wire, tinned wire, enameled wire, bare copper wire, copper-clad steel, copper cladding aluminum, etc. Left or right twisting direction can be selected freely.

| Model | OPS-300D | OPS-400D/ OPS -500D | OPS-630D | OPS-800D | OPS-800D |

| spool dia.(mm) | 300 | 400-500 | 630 | 800 | 1000 |

| max rotating speed (rpm) | 3000 | 3000 | 2000 | 2000 | 1500 |

| feeding wire dia. (mm) | 0.05-0.28 | 0.08- 0.45 | 0.12- 0.62 | 0.2-1.04 | 0.45-2.52 |

| twist cross section(mm²) | 0.035-0.45 | 0.035-2.5 | 0.18-6.0 | 0.8-16 | 6-35 |

| lay length(mm) | 10 Segment3.65-17.15 | 40 Segment6.3-50.4 | 34 Segment11.15-100 | 30 Segment20-160 | 34 Segment20-300 |

2, Double Twist Bunching Machine (Model: OPS-1250D – OPS -2500D)

Application: Main suitable for twisting copper wire, aluminum wire or PVC insulated wire below 7/19/37/61 strands to concentric twisting wire.

| Model | OPS-1250D | OPS -1600D | OPS -1800D | OPS -2000D | OPS -2240D | OPS -2500D |

| max. spool dia.(mm) | 1250 | 1600 | 1800 | 2000 | 2240 | 2500 |

| max. line speed(m/min) | 70-150 | 170-200 | 170-200 | 170-200 | 170-200 | 170-200 |

| max rotating speed (rpm) | 800 | 600 | 350 | 350 | 300 | 300 |

| feeding wire dia. (Al/Cu) (mm) | 1.0-3.0 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 |

| stand cross section(mm²) | 3.5-70 | 16-240 | 16-240 | 16-240 | 16-240 | 16-240 |

| compacting section (Cu) ( mm²) | 3.5-50 | 16-150 | 16-185 | 16-240 | 16-300 | 16-300 |

| compacting section (Al) ( mm²) | 3.5-70 | 16-240 | 16-240 | 16-300 | 16-400 | 16-400 |

| lay length(mm) | 40-350 | 40-350 | 50-600 | 60-600 | 60-600 | 60-600 |

| max. strand outer dia. (mm) | 15 | 25 | 35 | 35 | 35 | 35 |

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for Good Quality Copper Rod Upcast - Double Twist Bunching Machine PengSheng , The product will supply to all over the world, such as: Vietnam, Finland, London, We've a good reputation for stable quality solutions, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with customers both at home and abroad. We expect sincere cooperation and common development!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.

Write your message here and send it to us