Good quality Flux Cored Welding Wire Manufacturing Line - Flux Cored Welding Wire Production Line PengSheng

Good quality Flux Cored Welding Wire Manufacturing Line - Flux Cored Welding Wire Production Line PengSheng Detail:

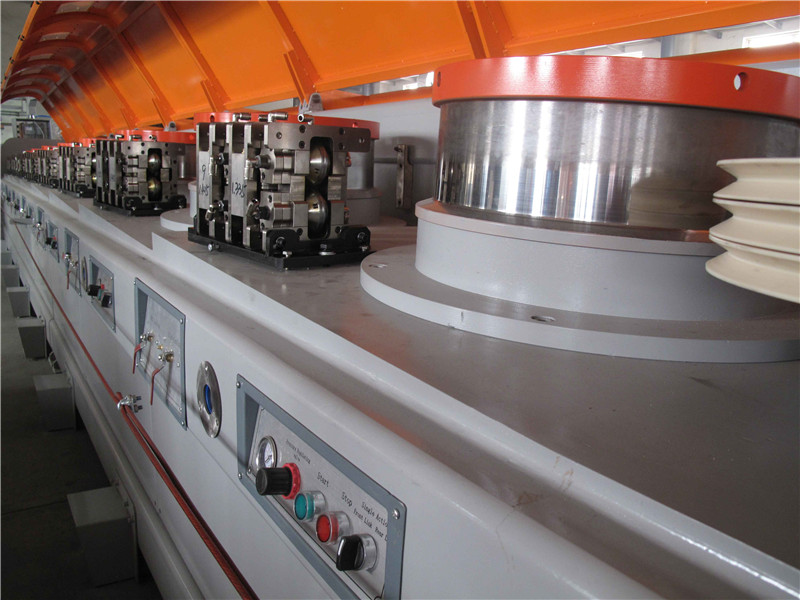

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

● Forming machine with powder feeding system

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

We have our own sales team, design team, technical team, QC team and package team. We have strict quality control procedures for each process. Also, all of our workers are experienced in printing field for Good quality Flux Cored Welding Wire Manufacturing Line - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: Mauritius, Pakistan, Roman, We follow superior mechanism to process these goods that ensure optimum durability and reliability of the goods. We follow latest effective washing and straightening processes that enable us to supply unmatched quality of items for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.

Write your message here and send it to us