High definition Drawn Steel Wire Production Line - Dry Steel Wire Drawing Machine PengSheng

High definition Drawn Steel Wire Production Line - Dry Steel Wire Drawing Machine PengSheng Detail:

Features

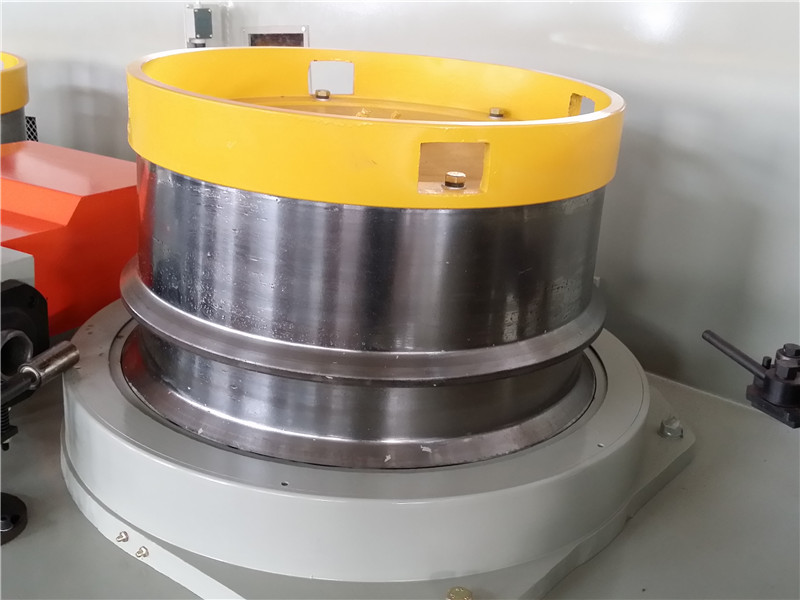

● Forged or casted capstan with hardness of HRC 58-62.

● High efficiency transmission with gear box or belt.

● Movable die box for easy adjustment and easy die changing.

● High performance cooling system for the capstan and die box

● High safety standard and friendly HMI control system

Available options

● Rotating die box with soap stirrers or rolling cassette

● Forged capstan and tungsten carbide coated capstan

● Accumulation of first drawing blocks

● Block stripper for coiling

● First level international electrical elements

Main technical specifications

|

Item |

LZn/350 |

LZn/450 |

LZn/560 |

LZn/700 |

LZn/900 |

LZn/1200 |

|

Drawing Capstan |

350 |

450 |

560 |

700 |

900 |

1200 |

|

Max. Inlet Wire Dia.(mm) |

4.3 |

5.0 |

7.5 |

13 |

15 |

20 |

|

Max. Inlet Wire Dia.(mm) |

3.5 |

4.0 |

6.0 |

9 |

21 |

26 |

|

Min. Outlet Wire Dia.(mm) |

0.3 |

0.5 |

0.8 |

1.5 |

2.4 |

2.8 |

|

Max. Working Speed(m/s) |

30 |

26 |

20 |

16 |

10 |

12 |

|

Motor Power(KW) |

11-18.5 |

11-22 |

22-45 |

37-75 |

75-110 |

90-132 |

|

Speed Control |

AC variable frequency speed control |

|||||

|

Noise Level |

Less than 80 dB |

|||||

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high quality regulate, reasonable price tag, excellent support and close co-operation with shoppers, we have been devoted to furnishing the best benefit for our buyers for High definition Drawn Steel Wire Production Line - Dry Steel Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Bolivia, US, Georgia, Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.