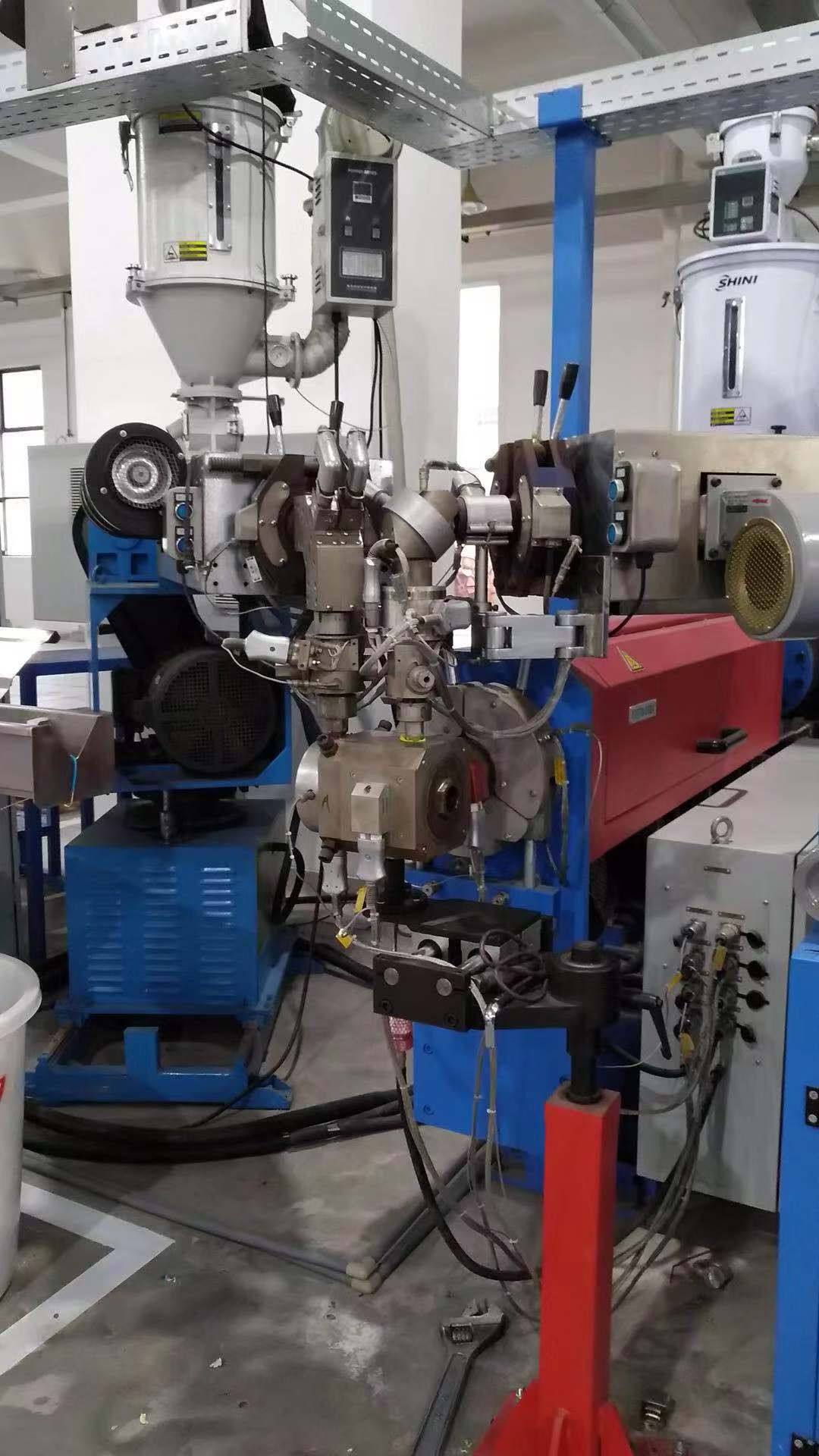

High-Efficiency Wire and Cable Extruders

Main characters

1, adopted excellent alloy while nitrogen treatment for screw and barrel, stable and long service life.

2, heating and cooling system is special designed while the temperature could be set in the range of 0-380℃ with high-precision control.

3, friendly operation by PLC+ touch screen

4, L/D ratio of 36:1 for special cable applications(physical foaming etc.)

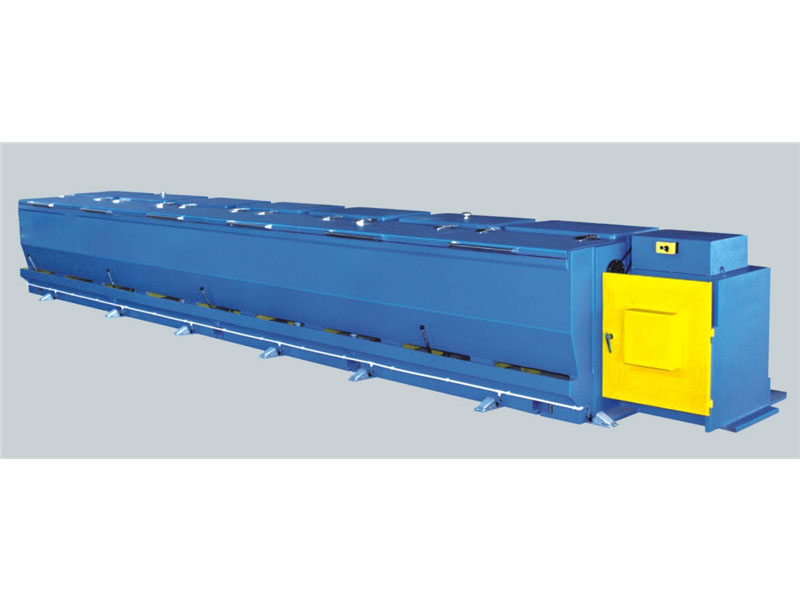

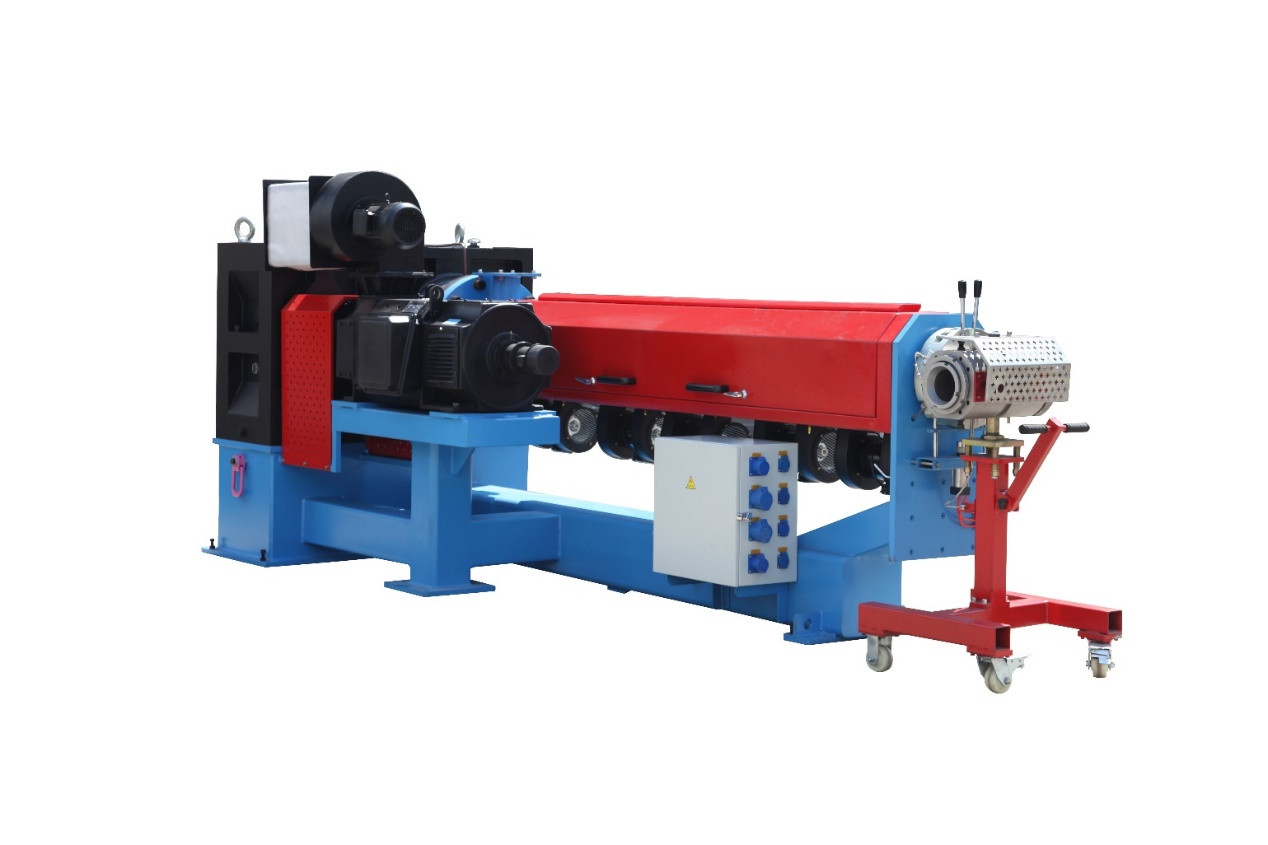

1.High efficiency extrusion machine

Application: Mainly used for insulation or sheath extrusion of wires and cables

| Model | Screw parameter | Extrusion capacity(kg/h) | Main Motor power(kw) | Outlet wire dia.(mm) | ||||

| Dia.(mm) | L/D ratio | Speed

(rpm) |

PVC | LDPE | LSHF | |||

| 30/25 | 30 | 25:1 | 20-120 | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 | 40 | 25:1 | 20-120 | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25:1 | 20-120 | 120 | 80 | 90 | 18.5 | 0.8-5 |

| 60/25 | 60 | 25:1 | 15-120 | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 | 70 | 25:1 | 15-120 | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 | 75 | 25:1 | 15-120 | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 | 80 | 25:1 | 10-120 | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 | 90 | 25:1 | 10-120 | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25:1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 | 120 | 25:1 | 5-90 | 800 | 470 | 540 | 132 | 8-80 |

| 150/25 | 150 | 25:1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 |

| 180/25 | 180 | 25:1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 |

| 200/25 | 200 | 25:1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 |

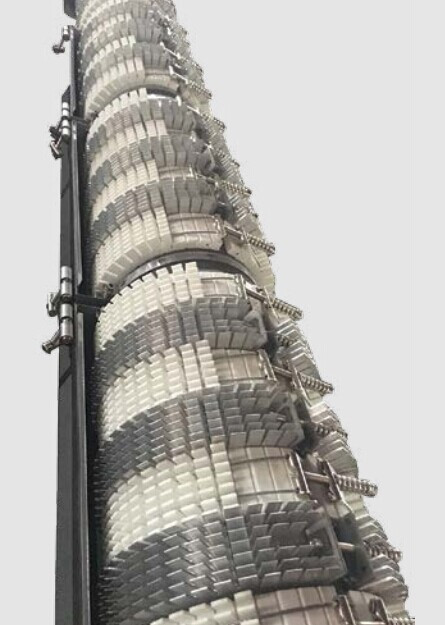

2.Double layer co-extrusion line

Application: Co-extrusion line is suitable for low smoke halogen free, XLPE extrusion, mainly used for production of nuclear power station cables, etc.

| Model | Screw parameter | Extrusion capacity (kg/h) | Inlet wire dia. (mm) | Outlet wire dia. (mm) | Line speed

(m/min) |

|

| Dia.(mm) | L/D ratio | |||||

| 50+35 | 50+35 | 25:1 | 70 | 0.6-4.0 | 1.0-4.5 | 500 |

| 60+35 | 60+35 | 25:1 | 100 | 0.8-8.0 | 1.0-10.0 | 500 |

| 65+40 | 65+40 | 25:1 | 120 | 0.8-10.0 | 1.0-12.0 | 500 |

| 70+40 | 70+40 | 25:1 | 150 | 1.5-12.0 | 2.0-16.0 | 500 |

| 80+50 | 80+50 | 25:1 | 200 | 2.0-20.0 | 4.0-25.0 | 450 |

| 90+50 | 90+50 | 25:1 | 250 | 3.0-25.0 | 6.0-35.0 | 400 |

3.Triple-extrusion line

Application: Triple-extrusion line is suitable for low smoke halogen free, XLPE extrusion, mainly used for production of nuclear power station cables, etc.

| Model | Screw parameter | Extrusion capacity (kg/h) | Inlet wire dia. (mm) | Line speed

(m/min) |

|

| Dia.(mm) | L/D ratio | ||||

| 65+40+35 | 65+40+35 | 25:1 | 120/40/30 | 0.8-10.0 | 500 |

| 70+40+35 | 70+40+35 | 25:1 | 180/40/30 | 1.5-12.0 | 500 |

| 80+50+40 | 80+50+40 | 25:1 | 250/40/30 | 2.0-20.0 | 450 |

| 90+50+40 | 90+50+40 | 25:1 | 350/100/40 | 3.0-25.0 | 400 |