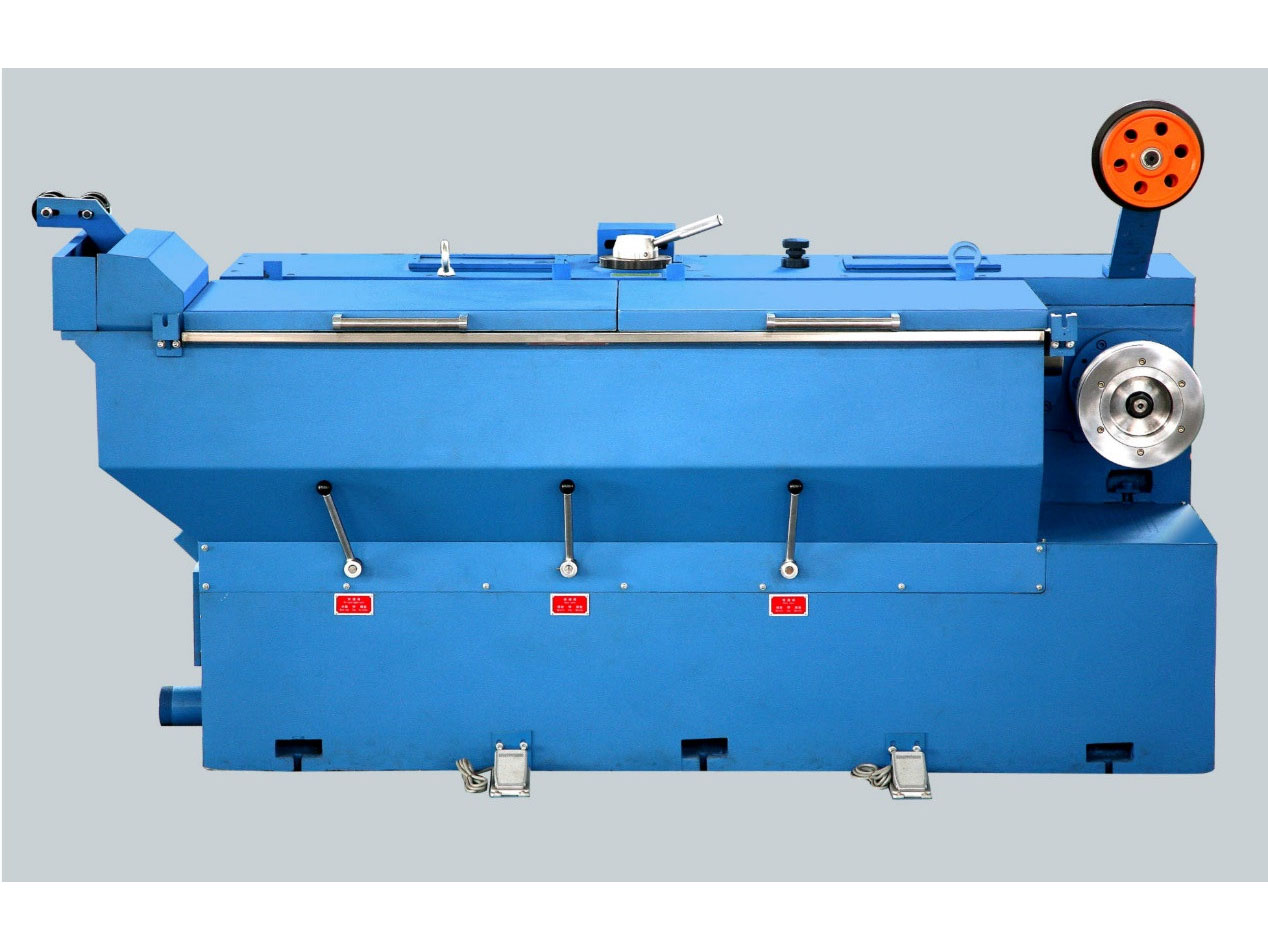

High Quality Continuous Casting And Rolling Mill - High-Efficiency Intermediate Drawing Machine PengSheng

High Quality Continuous Casting And Rolling Mill - High-Efficiency Intermediate Drawing Machine PengSheng Detail:

Productivity

• touchscreen display and control, high automatic operation

• single or double wire path design to meet different production requirements

Efficiency

• meets different finished product diameters

•force cooling/ lubrication system and sufficient protection technology for transmission to safeguard machine with long service life

Main technical data

| Type | ZL250-17 | ZL250B-17 | DZL250-17 | DZL250B-17 |

| Material | Cu | Al/Al-Alloys | Cu | Al/Al-Alloys |

| Max inlet Ø [mm] | 3.5 | 4.2 | 3.0 | 4.2 |

| Outlet Ø range [mm] | 0.32-2.76 | 0.4-2.76 | 0.4-2.0 | 0.4-2.0 |

| No. of wires | 1 | 1 | 2 | 2 |

| No. of drafts | 9/17 | 9/17 | 9/17 | 9/17 |

| Max. speed [m/sec] | 30 | 30 | 30 | 30 |

| Wire elongation per draft | 18%-25% | 13%-18% | 18%-25% | 13%-18% |

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for High Quality Continuous Casting And Rolling Mill - High-Efficiency Intermediate Drawing Machine PengSheng , The product will supply to all over the world, such as: Singapore, Montpellier, Islamabad, We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

Write your message here and send it to us