Hot New Products Aluminum Clad Steel Wire Continuous Cladding Machine - High-Efficiency Fine Wire Drawing Machine PengSheng

Hot New Products Aluminum Clad Steel Wire Continuous Cladding Machine - High-Efficiency Fine Wire Drawing Machine PengSheng Detail:

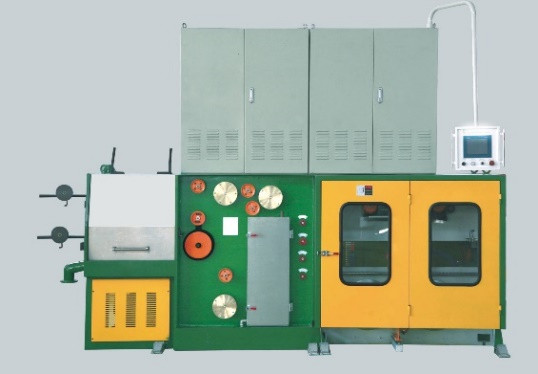

Fine Wire Drawing Machine

• transmitted by high quality flat belts, low noise.

• double converter drive, constant tension control, energy saving

• traverse by ball scre

| Type | BD22/B16 | B22 | B24 |

| Max inlet Ø [mm] | 1.6 | 1.2 | 1.2 |

| Outlet Ø range [mm] | 0.15-0.6 | 0.1-0.32 | 0.08-0.32 |

| No. of wires | 1 | 1 | 1 |

| No. of drafts | 22/16 | 22 | 24 |

| Max. speed [m/sec] | 40 | 40 | 40 |

| Wire elongation per draft | 15%-18% | 15%-18% | 8%-13% |

Fine Wire Drawing Machine with High-Capacity Spooler

• compact design for space saving

• high-capacity spooler for loading more wire

| Type | DB22 | DB24 |

| Max inlet Ø [mm] | 1.2 | 1.2 |

| Outlet Ø range [mm] | 0.1-0.32 | 0.08-0.32 |

| No. of wires | 1 | 1 |

| No. of drafts | 22 | 24 |

| Max. speed [m/sec] | 40 | 40 |

| Wire elongation per draft | 15%-18% | 8%-13% |

Fine Wire Drawing Machine with Annealer

• compact design for space saving

• DC 3sections design and digital voltage control for annealer

• single or double spoolers to meet different requirement

• double spoolers model with fully automatic spooler changing system for continuous production.

| Type | BDT22/16 | BT22 | BT24 |

| Max inlet Ø [mm] | 1.6 | 1.2 | 1.2 |

| Outlet Ø range [mm] | 0.15-0.7 | 0.1-0.4 | 0.1-0.4 |

| No. of wires | 1 | 1 | 1 |

| No. of drafts | 22/16 | 22 | 24 |

| Max. speed [m/sec] | 40 | 40 | 40 |

| Wire elongation per draft | 15%-18% | 15%-18% | 8%-13% |

| Max. annealing power (KVA) | 45 | 20 | 20 |

| Max. annealing current (A) | 600 | 240 | 240 |

| No. of spools | 1/2 | 1/2 | 1/2 |

Product detail pictures:

Related Product Guide:

Our goods are broadly recognized and reliable by users and can meet consistently switching financial and social demands of Hot New Products Aluminum Clad Steel Wire Continuous Cladding Machine - High-Efficiency Fine Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Japan, British, Sydney, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

We have been looking for a professional and responsible supplier, and now we find it.

Write your message here and send it to us