Hot Selling for Stainless Steel Welding Wire Production Line - Dry Steel Wire Drawing Machine PengSheng

Hot Selling for Stainless Steel Welding Wire Production Line - Dry Steel Wire Drawing Machine PengSheng Detail:

Features

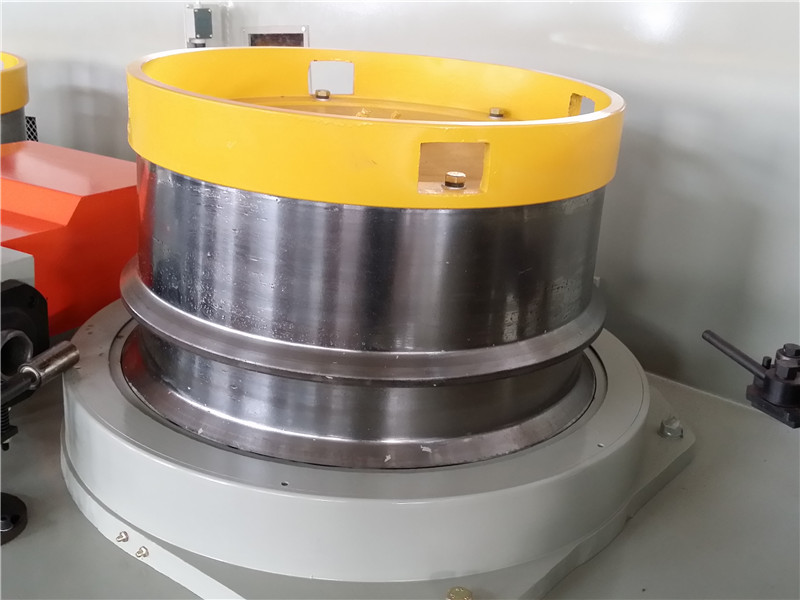

● Forged or casted capstan with hardness of HRC 58-62.

● High efficiency transmission with gear box or belt.

● Movable die box for easy adjustment and easy die changing.

● High performance cooling system for the capstan and die box

● High safety standard and friendly HMI control system

Available options

● Rotating die box with soap stirrers or rolling cassette

● Forged capstan and tungsten carbide coated capstan

● Accumulation of first drawing blocks

● Block stripper for coiling

● First level international electrical elements

Main technical specifications

|

Item |

LZn/350 |

LZn/450 |

LZn/560 |

LZn/700 |

LZn/900 |

LZn/1200 |

|

Drawing Capstan |

350 |

450 |

560 |

700 |

900 |

1200 |

|

Max. Inlet Wire Dia.(mm) |

4.3 |

5.0 |

7.5 |

13 |

15 |

20 |

|

Max. Inlet Wire Dia.(mm) |

3.5 |

4.0 |

6.0 |

9 |

21 |

26 |

|

Min. Outlet Wire Dia.(mm) |

0.3 |

0.5 |

0.8 |

1.5 |

2.4 |

2.8 |

|

Max. Working Speed(m/s) |

30 |

26 |

20 |

16 |

10 |

12 |

|

Motor Power(KW) |

11-18.5 |

11-22 |

22-45 |

37-75 |

75-110 |

90-132 |

|

Speed Control |

AC variable frequency speed control |

|||||

|

Noise Level |

Less than 80 dB |

|||||

Product detail pictures:

Related Product Guide:

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for Hot Selling for Stainless Steel Welding Wire Production Line - Dry Steel Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Benin, Holland, Ecuador, We take measure at any price to attain essentially the most up-to-date gear and procedures. The packing of nominated brand is our a further distinguishing feature. The solutions to assure years of trouble-free service has attracted a great deal customers. The goods are obtainable in improved designs and richer variety, they're produced scientifically of purely raw supplies. It accessible in a variety of designs and specifications for the selection. The newest forms are much far better than the previous one and they're extremely popular with several clients.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!