Manufacturer for Aluminum Rod Casting And Rolling Machine - Up Casting system of Cu-OF Rod PengSheng

Manufacturer for Aluminum Rod Casting And Rolling Machine - Up Casting system of Cu-OF Rod PengSheng Detail:

Raw material

Good quality copper cathode is suggested to be the raw material for the production to ensure the high mechanical and electrical quality product.

Some percentage of recycled copper could be used too. The de-oxygen time in the furnace will be longer and that may shorter the working life of the furnace. A separte melting furnace for the copper scrap could be installed before the melting furnace to use full recycled copper.

Furnace

Bricks and sand built with melting channels, the furnace is electrically induction heated with various melting capacities. Heating power could be adjusted manually or automaticly to keep the molten copper in the controlled temperature range. The heating principle itself and optimized furnace structure design allow the max. power using and the highest efficiency.

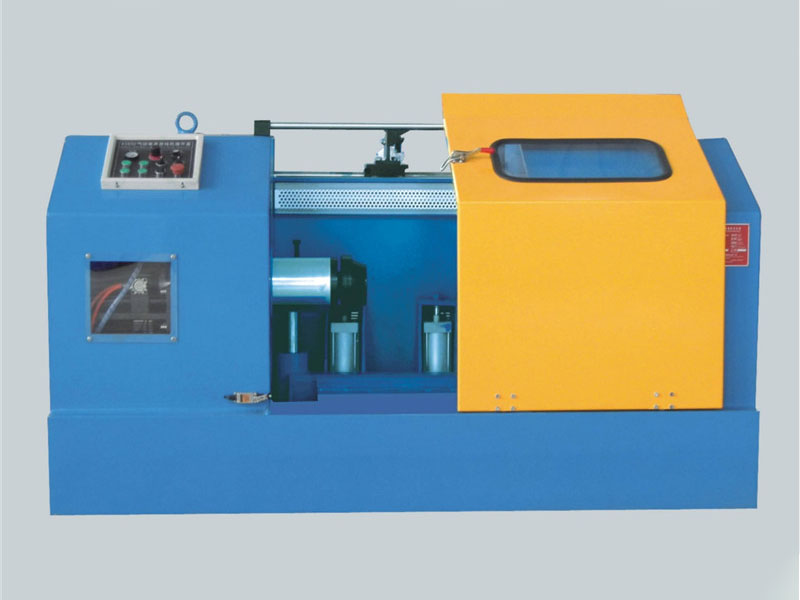

Casting machine

The copper rod or tube is cooled and casted by the cooler. The coolers are fixed on the casting machine frame above the holding furnace. With the servomotor driving system, the casted products are pull upward through the coolers. The solid product after cooling is guided to double coilers or cut-to length machine where to have the final coils or length product.

The machine could work with two different sizes simultaneously when equip with two sets of servo driving system. It is easy to produce different sizes by changing related coolers and dies.

Overview

Casting machine and furnace

Charging device

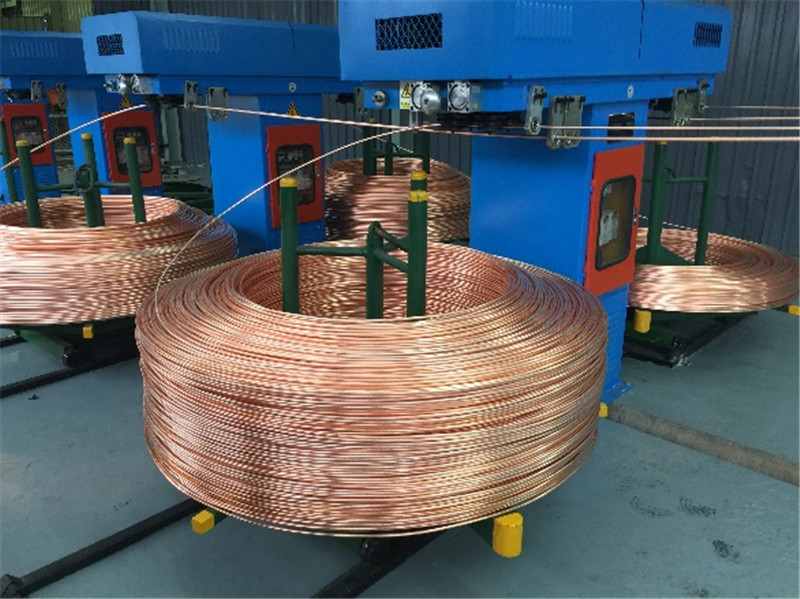

Take-up machine

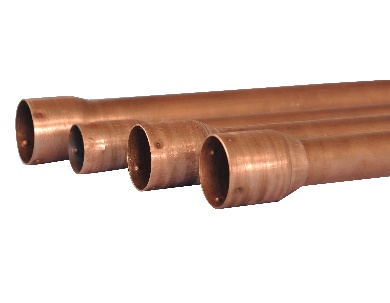

Product

On-site service

Main technical data

|

Annual capacity(Tons/Year) |

2000 |

3000 |

4000 |

6000 |

8000 |

10000 |

12000 |

15000 |

|

cooler pieces |

4 |

6 |

8 |

12 |

16 |

20 |

24 |

28 |

|

Rod Dia. in mm |

8,12,17,20,25, 30 and special size demand can be customized |

|||||||

|

Power Consumption |

315 to 350 kwh/ton production |

|||||||

|

Pulling |

Servo motor and inverter |

|||||||

|

Charging |

Manual or automatic type |

|||||||

|

Control |

PLC and touch screen operation |

|||||||

Supply of spare parts

Fusion channel

Shaped brick

Light temperature-keeping brick

Crystallizer assembly

Inner tube of crystallizer

Water tube of crystallizer

Quick joint

Graphite die

Graphite protective case & lining

Asbestos rubber blanket

Nano insulation board

Cr fiber blanket

Product detail pictures:

Related Product Guide:

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Manufacturer for Aluminum Rod Casting And Rolling Machine - Up Casting system of Cu-OF Rod PengSheng , The product will supply to all over the world, such as: Karachi, Paris, Malaysia, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!