Manufacturer for Continuous Sheathing Machine - High-Efficiency Fine Wire Drawing Machine PengSheng

Manufacturer for Continuous Sheathing Machine - High-Efficiency Fine Wire Drawing Machine PengSheng Detail:

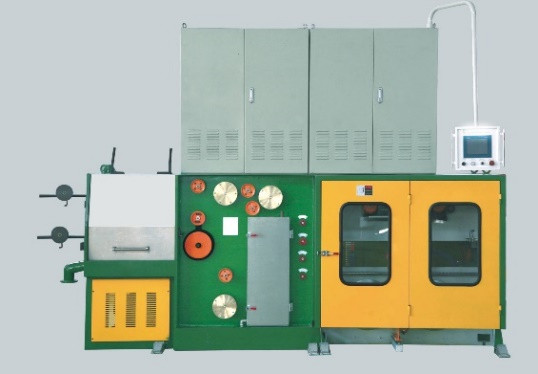

Fine Wire Drawing Machine

• transmitted by high quality flat belts, low noise.

• double converter drive, constant tension control, energy saving

• traverse by ball scre

| Type | BD22/B16 | B22 | B24 |

| Max inlet Ø [mm] | 1.6 | 1.2 | 1.2 |

| Outlet Ø range [mm] | 0.15-0.6 | 0.1-0.32 | 0.08-0.32 |

| No. of wires | 1 | 1 | 1 |

| No. of drafts | 22/16 | 22 | 24 |

| Max. speed [m/sec] | 40 | 40 | 40 |

| Wire elongation per draft | 15%-18% | 15%-18% | 8%-13% |

Fine Wire Drawing Machine with High-Capacity Spooler

• compact design for space saving

• high-capacity spooler for loading more wire

| Type | DB22 | DB24 |

| Max inlet Ø [mm] | 1.2 | 1.2 |

| Outlet Ø range [mm] | 0.1-0.32 | 0.08-0.32 |

| No. of wires | 1 | 1 |

| No. of drafts | 22 | 24 |

| Max. speed [m/sec] | 40 | 40 |

| Wire elongation per draft | 15%-18% | 8%-13% |

Fine Wire Drawing Machine with Annealer

• compact design for space saving

• DC 3sections design and digital voltage control for annealer

• single or double spoolers to meet different requirement

• double spoolers model with fully automatic spooler changing system for continuous production.

| Type | BDT22/16 | BT22 | BT24 |

| Max inlet Ø [mm] | 1.6 | 1.2 | 1.2 |

| Outlet Ø range [mm] | 0.15-0.7 | 0.1-0.4 | 0.1-0.4 |

| No. of wires | 1 | 1 | 1 |

| No. of drafts | 22/16 | 22 | 24 |

| Max. speed [m/sec] | 40 | 40 | 40 |

| Wire elongation per draft | 15%-18% | 15%-18% | 8%-13% |

| Max. annealing power (KVA) | 45 | 20 | 20 |

| Max. annealing current (A) | 600 | 240 | 240 |

| No. of spools | 1/2 | 1/2 | 1/2 |

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new merchandise into the market each and every year for Manufacturer for Continuous Sheathing Machine - High-Efficiency Fine Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: Peru, Poland, Paris, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!

Write your message here and send it to us