Manufacturer for Continuous Sheathing Machine - Horizontal DC Resistance Annealer PengSheng

Manufacturer for Continuous Sheathing Machine - Horizontal DC Resistance Annealer PengSheng Detail:

Productivity

• annealing voltage could be chose to meet different wire requirement

• single or double wire path design to meet different drawing machine

Efficiency

• water cooling of contact wheel from inner to outside design improves the service life of bearings and nickel ring effectively

| Type | TH5000 | STH8000 | TH3000 | STH3000 |

| No. of wires | 1 | 2 | 1 | 2 |

| Inlet Ø range [mm] | 1.2-4.0 | 1.2-3.2 | 0.6-2.7 | 0.6-1.6 |

| Max. speed [m/sec] | 25 | 25 | 30 | 30 |

| Max. annealing power (KVA) | 365 | 560 | 230 | 230 |

| Max. annealing voltage (V) | 60 | 60 | 60 | 60 |

| Max. annealing current (A) | 5000 | 8000 | 3000 | 3000 |

| Protection system |

nitrogen or steam atmosphere |

|||

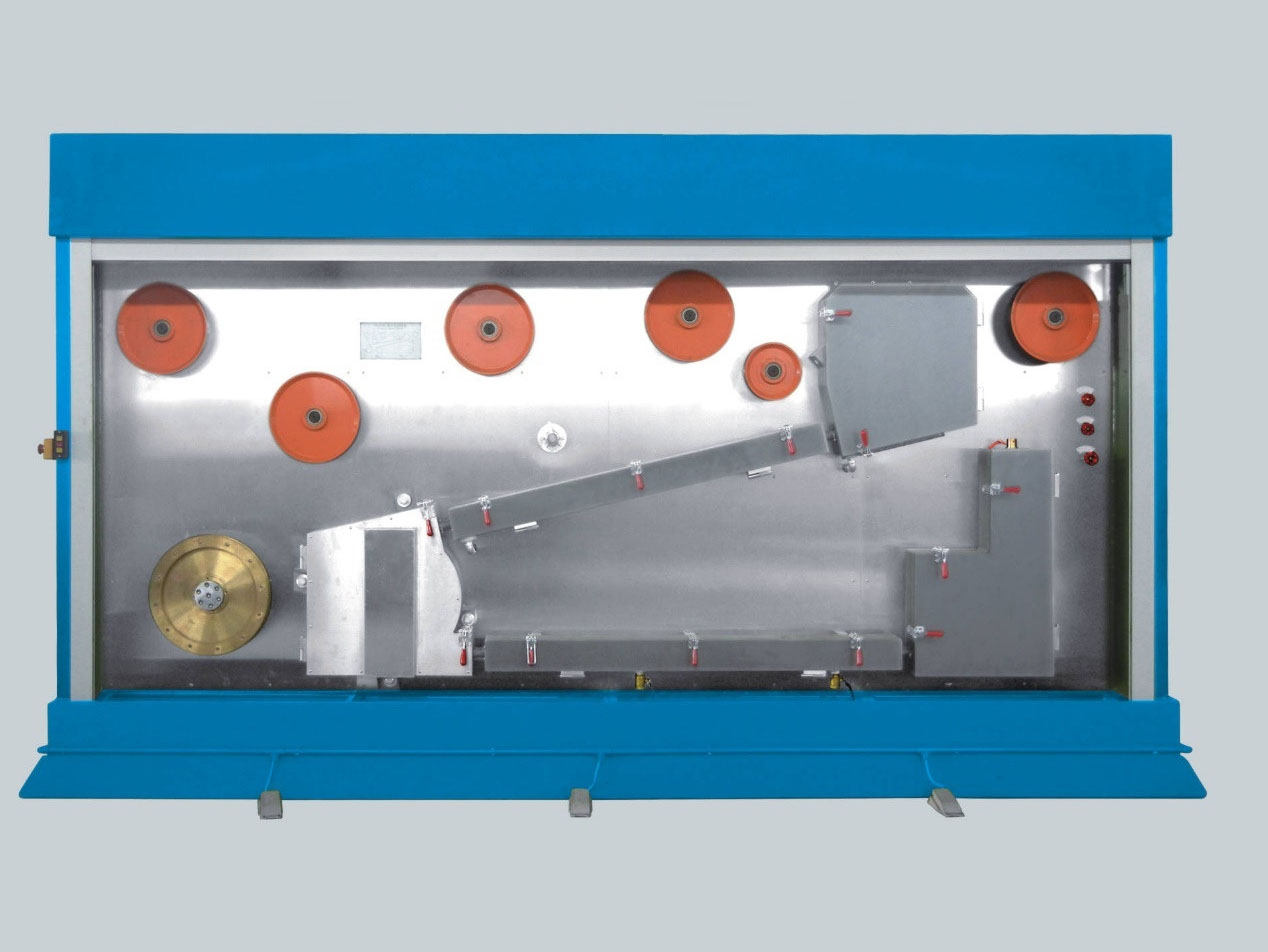

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for Manufacturer for Continuous Sheathing Machine - Horizontal DC Resistance Annealer PengSheng , The product will supply to all over the world, such as: Malta, European, Serbia, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

Write your message here and send it to us