New Arrival China Mig Welding Wire Plant - Flux Cored Welding Wire Production Line PengSheng

New Arrival China Mig Welding Wire Plant - Flux Cored Welding Wire Production Line PengSheng Detail:

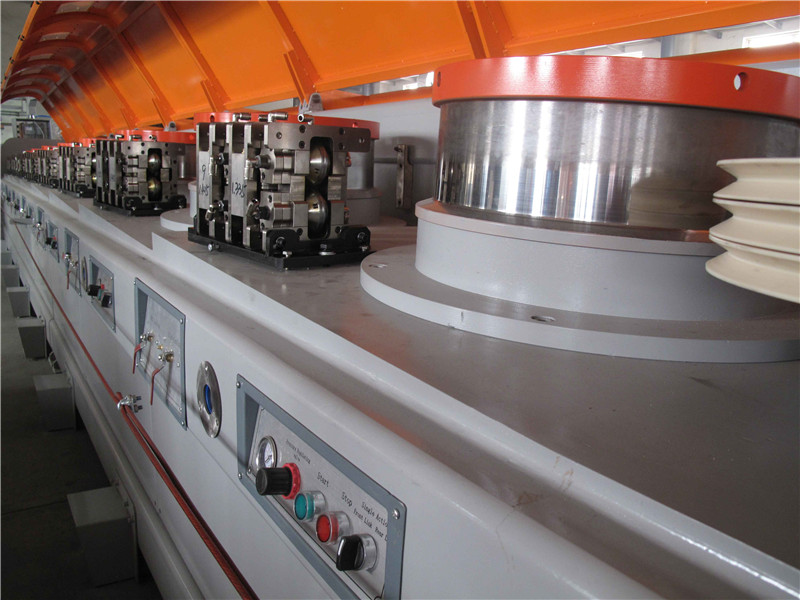

The line is composed by following machines

● Strip pay-off

● Strip surface cleaning unit

● Forming machine with powder feeding system

● Rough drawing and fine drawing machine

● Wire surface cleaning and oiling machine

● Spool take-up

● Layer rewinder

Main technical specifications

|

Steel strip material |

Low carbon steel, stainless steel |

|

Steel strip width |

8-18mm |

|

Steel tape thickness |

0.3-1.0mm |

|

Feeding speed |

70-100m/min |

|

Flux filling accuracy |

±0.5% |

|

Final drawn wire size |

1.0-1.6mm or as customer required |

|

Drawing line speed |

Max. 20m/s |

|

Motor/PLC/Electrical elements |

SIEMENS/ABB |

|

Pneumatic parts/Bearings |

FESTO/NSK |

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for New Arrival China Mig Welding Wire Plant - Flux Cored Welding Wire Production Line PengSheng , The product will supply to all over the world, such as: Belgium, Botswana, Bolivia, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional products and vast knowledge of technology makes us the preferred choice for our customers.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!

Write your message here and send it to us