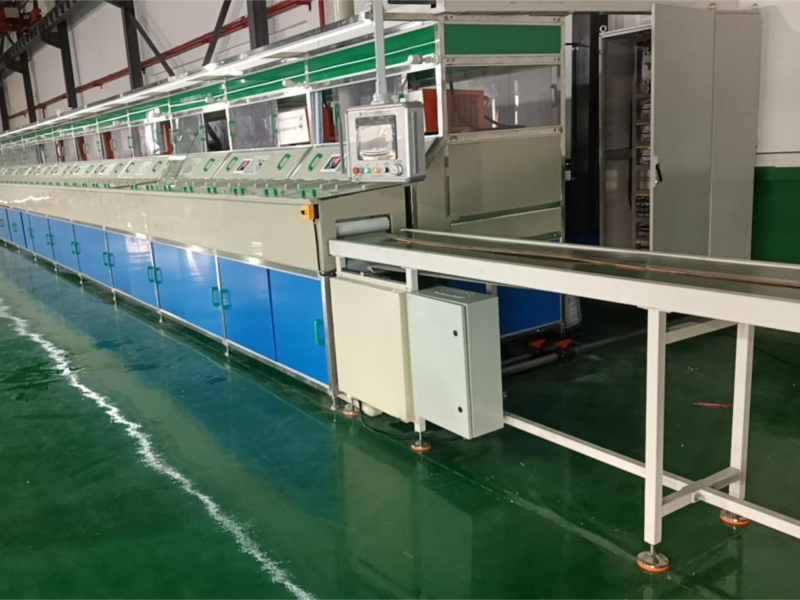

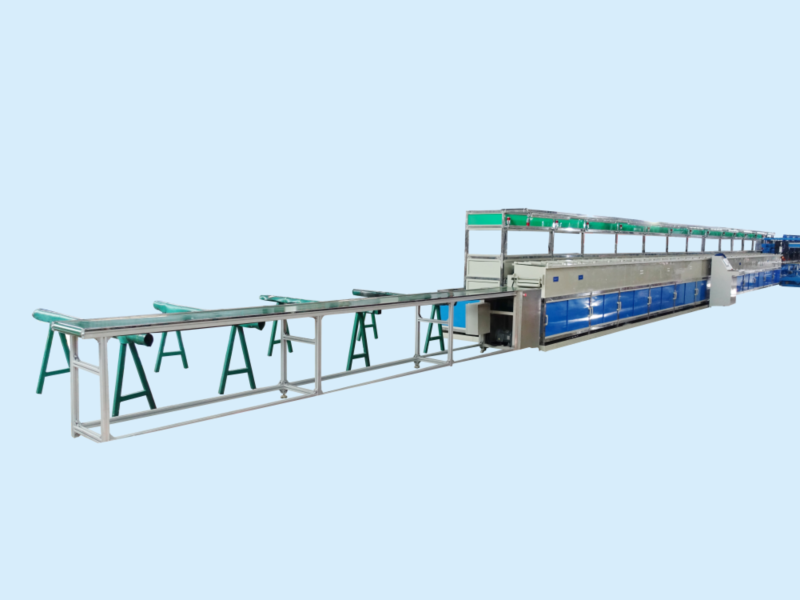

Description to main component:

1. Copper busbar Tin Plating Machine feeding rack:

Put the bright busbar horizontally on the feeding rack; the rack can automatically turn over the busbar to vertical status and send it to the cleaning channel by feeding rollers.

2. Copper busbar Tin Plating Line Degreasing cleaning section:

After receiving the signal, the hauling device will clamp the busbar and the conductive wheels will contact the busbar. During this section, the busbar will go through the electrolytic degreasing and oil removing process.

3. Copper busbar Tin Coating Machine 3-section water cleaning:

This process it to clean the oil and the acid at the surface of busbar

4. Copper busbar Tin Coating Line Excitation processing section:

Excitation processing section process is the last cleaning paragraph before the tin plating.

5. Plating Line For Copper busbar Tin plating section:

Tin plating section is divided into three parts, which can ensure the busbar get the uniform plating effect and plating thickness.

6. 3-section water cleaning after plating:

This process is to clean the residual acid at the surface of busbar

7. Warm water cleaning section:

This process is for the further cleaning

8. Take up and overturn rack:

After the tin plating, the vertical busbars pass the conveying roller rail, then turn to the horizontal status and slip into the stacking device through rubber wheels. In order to avoid the scratch, the slipping distance can be adjusted.

9. Electric control system:

Relay: OMRON

Contactor: CHINT

Breaker: CHINT

Drive: Delta

PLC: Mitsubishi

Short Description:

OCTP 300/600 Copper Busbar Tin plating is matured and advanced continuous plating process line for busbar Tin plating with plating length range ≥3000 mm, width range 15 to 300 mm, thickness range 3-20 mm, and the speed range of 5~20 m/min.

Advantages:

● The line changes the way of traditional hanging plating to conventional way, which improves the efficiency, surface quality and performance of the plating corrosion resistance.

● Small floor space, low flux consumption, environment friendly, and advanced production process, etc.

● The cleaning and plating section are all automatic running, only needs feeding and packing manpower for the line.

● The line also could be equipped with feeding and offloading mechanical arm which can matched with the hydraulic drawing machine.

● This line works in a closed condition and trough stepless speed regulation microcomputer to control, the busbar gets continuously tin plated under high density of current.

● The waste air treatment ratio is more than 98% and waste water treatment ratio is 100%.

● Multi pieces busbars can be plated synchronously when busbar width is less than 150 mm.

Post time: Feb-08-2025