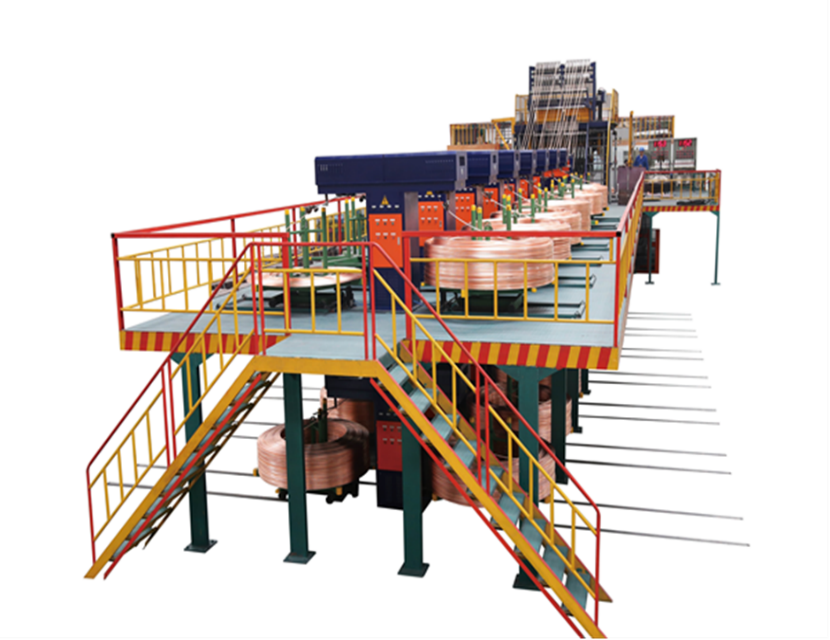

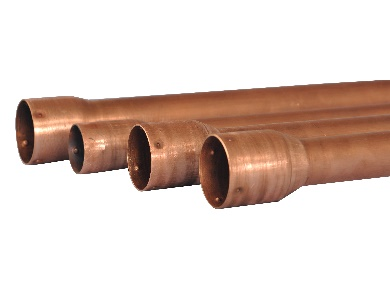

The Up Casting system is mainly used to produce high quality oxygen free copper rod for wire and cable industries. With some special design, it is capable to make some copper alloys for various applications or some profiles like tubes and bus bar.

The system is with characters of high quality product, low investment, easy operation, low running cost, flexible in changing production size and no pollution to environment.

Excepting the Up-casting machine line, we provide spare parts for up-casting machine. For example, Casting graphite dies, graphite protection cup , crystallizer and furnace rebuilding materials,etc.

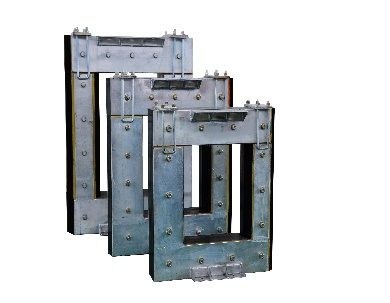

1. Casting graphite dies, graphite protection cup , crystallizer for Casting machine

The copper rod is cooled and casted by the crystallizer .Casting graphite dies are inset in to the furnace for casting the copper liquid at the start. Graphite protection cup is used for protecting the crystallizer. Good quality dies and protection cup will be good for the quality of copper rodand it will reduce the cost on dies and protection cup consumption.

The crystallizer are fixed on the casting machine frame above the holding furnace. With the servomotor driving system, the casted products are pull upward through the coolers. The solid product after cooling is guided to double coilers or cut-to length machine where to have the final coils or length product. After changing different size crystallizer, the machine can produce copper rod with different size.

2.Furnace rebuilding materials

Bricks and sand built with melting channels, the furnace is electrically induction heated with various melting capacities. Heating power could be adjusted manually or automaticly to keep the molten copper in the controlled temperature range. The heating principle itself and optimized furnace structure design allow the max. power using and the highest efficiency. We supply the bricks , sand and other rebuilding materials for furnace .

Supply of our spare parts for Up Casting Machine

Iron core

Induction coil

Cooling water jacket

Fusion channel

Shaped brick

Light temperature-keeping brick

Crystallizer assembly

Crystallizer assembly

Water tube of crystallizer

Quick joint

Graphite die

Graphite protective case & lining

Asbestos rubber blanket

Nano insulation board

Cr fiber blanket

Post time: Dec-01-2022