If you’re in the electrical or manufacturing industry, you’ve likely heard about copper busbar tin plating machine or copper busbar silver plating machine. But do you know how effective they can improve your business? Beijing Orient Pengsheng Tech. Co., Ltd. will introduce why these machines are worth your attention. By the end, you’ll understand how they can boost efficiency, reduce costs, and improve product quality.

What Are Copper Busbar Tin Plating Machine and Copper Busbar Silver Plating Machine?

Copper busbars are essential components in electrical systems, but raw copper has its limitations. Over time, copper can oxidize, leading to reduced conductivity and potential system failures. This is where plating machines come in.

A Copper Busbar Tin Plating Machine or Copper Busbar Tin Electroplating Machine applies a thin layer of tin or silver to the copper busbar surface. Tin or silver plating enhances conductivity, prevents corrosion, and improves solderability. In comparison, Copper Busbar Silver Electroplating Machine uses silver plating for even higher conductivity and superior performance.

Why Plating Matters for Copper Busbars

Plating process is a necessity for modern electrical systems. Here’s why:

1. Enhanced Conductivity: Both copper busbar tin plating machine and copper busbar silver plating machine improve electrical performance, ensuring consistent power distribution.

2. Corrosion Resistance: Plating creates a protective barrier, preventing oxidation and extending the service life of copper busbar.

3. Cost Efficiency: By reducing maintenance and replacement costs, plating machines offer a high return on investment.

4. Versatility: Whether you need tin for standard applications or silver for high-performance production line, there’s a machine for you need.

How Advanced Plating Machines Work

Beijing Orient Pengsheng Tech. Co., Ltd. has spent years researching and refining our fully automated, continuous Copper Busbar Tin Plating Machine and Copper Busbar Silver Plating Machine. These machines combined China top technology with practical efficiency.

Here’s how they stand out:

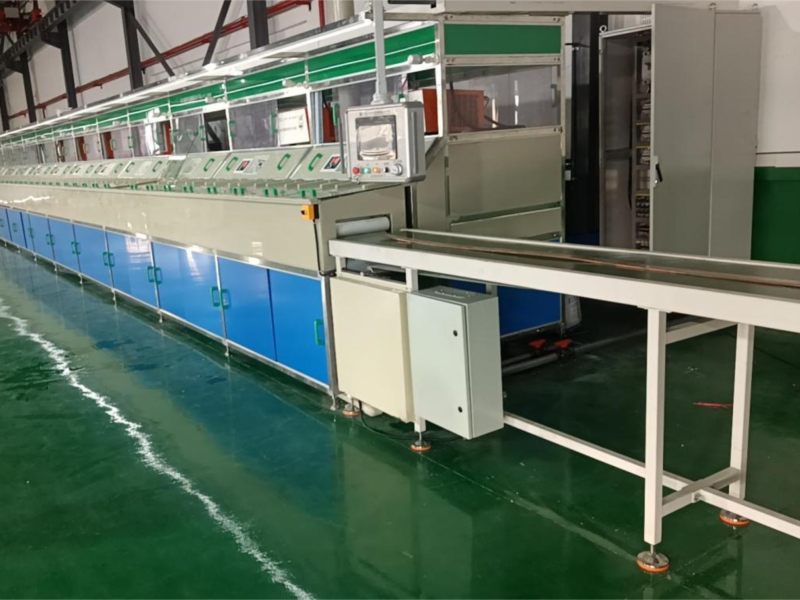

Beijing Orient Pengsheng Tech. Co., Ltd. has spent years researching and refining our fully automated, continuous copper busbar tin / silver plating machine. This line takes the most advanced continuous plating technology and applies it perfectly to copper busbar tin / silver plating. These two production lines eliminate the flaws of older methods. With a fully enclosed design and PLC-controlled variable speed adjustment, it allows copper busbar (≥3000mm in length, 15-300mm in width, and 3-20mm in thickness) to move continuously at 0-20m/min under high current density. The entire process is fully automated. The workflow is environmentally friendly. The gas collection exceeds 98%, and wastewater is fully recycled (100% collection rate). There’s no need for hanging, and multiple copper busbars (up to 150mm wide) can be plated at the same time.

Unlike traditional hanging electroplating, which often results in inconsistent coatings, our system ensures a uniform, smooth, and precise tin or silver layer with strong adhesion and excellent corrosion resistance.

Tin Plating vs. Silver Plating: Which Is Right for You?

When choosing between a Copper Busbar Tin Plating Machine and a Copper Busbar Silver Plating Machine, it’s important to consider your specific needs.

- Tin Plating: Ideal for standard electrical applications, tin plating offers excellent conductivity and corrosion resistance at a lower cost.

- Silver Plating: For high-performance systems, silver plating provides superior conductivity and durability.

Both options are available in electroplating versions, ensuring precision and consistency for production line.

The Economic and Environmental Benefits

Investing in a Copper Busbar Tin Electroplating Machine or Copper Busbar Silver Electroplating Machine isn’t just about improving product quality—it’s also about saving money and also protect environmental.

The equipment takes up minimal space (only about 40% of the area required for a traditional line), uses less plating solution (around 50% of what a traditional line consumes), and provides a much better working environment. The process is highly automated, only loading and packaging need manual operation. Automatic mechanical arms can be used for loading and unloading. From cleaning to tin plating, everything runs automatically, with no manual operation required except for startup monitoring. In terms of efficiency, this new production line is 3-5 times faster than a traditional line. It can process extra-long copper busbars without any limitations and has an initial investment cost that’s the same or even lower than a traditional line.

Developed and manufactured by our company, this is currently the most advanced copper bar tin plating machine in China.

Why Choose Our Machines?

Our Copper Busbar Tin Plating Machine and Copper Busbar Silver Plating Machine are designed to provide high performance and efficiency. The full production line includes:

- A tin or silver plating line with electrical control, digital temperature control, and a heating/cooling system.

- A waste gas treatment system with a 98% collection rate.

- A zero-discharge wastewater treatment system.

These features ensure high efficiency, energy savings, and smart manufacturing—for the perfect products.

Final Thoughts

Whether you’re looking for a Copper Busbar Tin Plating Machine or a Copper Busbar Silver Plating Machine. The suitable machine can improve your operations. With advanced automation, eco-friendly design, and high efficiency, these machines are the future of copper busbar production.

Ready to take your business to the next level? Contact us today to learn more about our customized plating solutions!

Post time: Mar-25-2025