OEM manufacturer Vertical Steel Wire Drawing Machine - Dry Steel Wire Drawing Machine PengSheng

OEM manufacturer Vertical Steel Wire Drawing Machine - Dry Steel Wire Drawing Machine PengSheng Detail:

Features

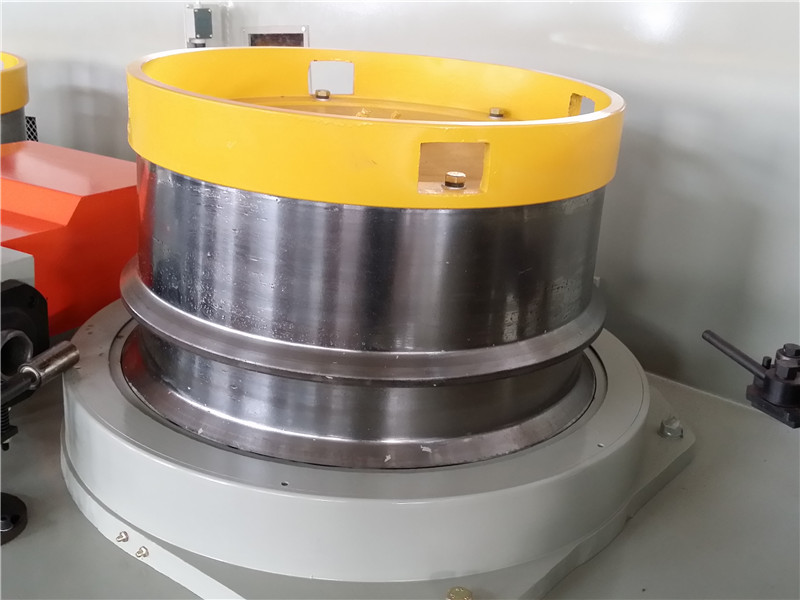

● Forged or casted capstan with hardness of HRC 58-62.

● High efficiency transmission with gear box or belt.

● Movable die box for easy adjustment and easy die changing.

● High performance cooling system for the capstan and die box

● High safety standard and friendly HMI control system

Available options

● Rotating die box with soap stirrers or rolling cassette

● Forged capstan and tungsten carbide coated capstan

● Accumulation of first drawing blocks

● Block stripper for coiling

● First level international electrical elements

Main technical specifications

|

Item |

LZn/350 |

LZn/450 |

LZn/560 |

LZn/700 |

LZn/900 |

LZn/1200 |

|

Drawing Capstan |

350 |

450 |

560 |

700 |

900 |

1200 |

|

Max. Inlet Wire Dia.(mm) |

4.3 |

5.0 |

7.5 |

13 |

15 |

20 |

|

Max. Inlet Wire Dia.(mm) |

3.5 |

4.0 |

6.0 |

9 |

21 |

26 |

|

Min. Outlet Wire Dia.(mm) |

0.3 |

0.5 |

0.8 |

1.5 |

2.4 |

2.8 |

|

Max. Working Speed(m/s) |

30 |

26 |

20 |

16 |

10 |

12 |

|

Motor Power(KW) |

11-18.5 |

11-22 |

22-45 |

37-75 |

75-110 |

90-132 |

|

Speed Control |

AC variable frequency speed control |

|||||

|

Noise Level |

Less than 80 dB |

|||||

Product detail pictures:

Related Product Guide:

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for OEM manufacturer Vertical Steel Wire Drawing Machine - Dry Steel Wire Drawing Machine PengSheng , The product will supply to all over the world, such as: azerbaijan, Finland, Bolivia, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.