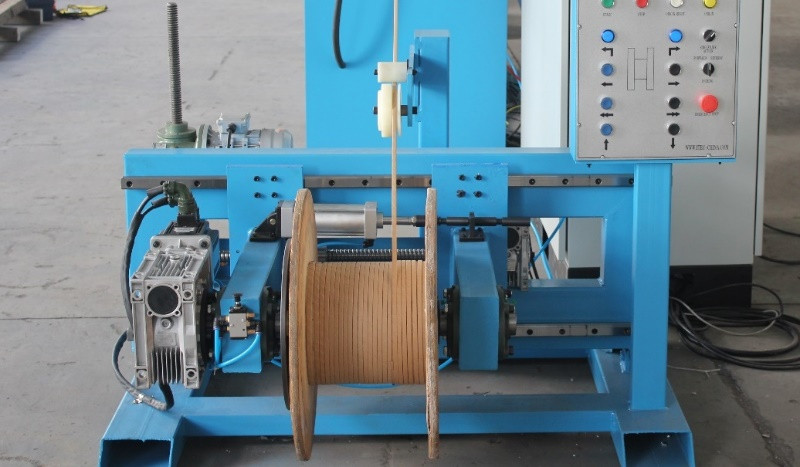

OEM/ODM China Magnet Wire Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng

OEM/ODM China Magnet Wire Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng Detail:

Main technical data

Conductor area: 5 mm²—120mm²(or customized)

Covering layer: 2 or 4 times of layers

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

Taping head

Caterpillar

Take-up

Product detail pictures:

Related Product Guide:

We are commitment to offer the competitive price ,outstanding products quality, as well as fast delivery for OEM/ODM China Magnet Wire Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng , The product will supply to all over the world, such as: Iran, Cannes, Nepal, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Write your message here and send it to us