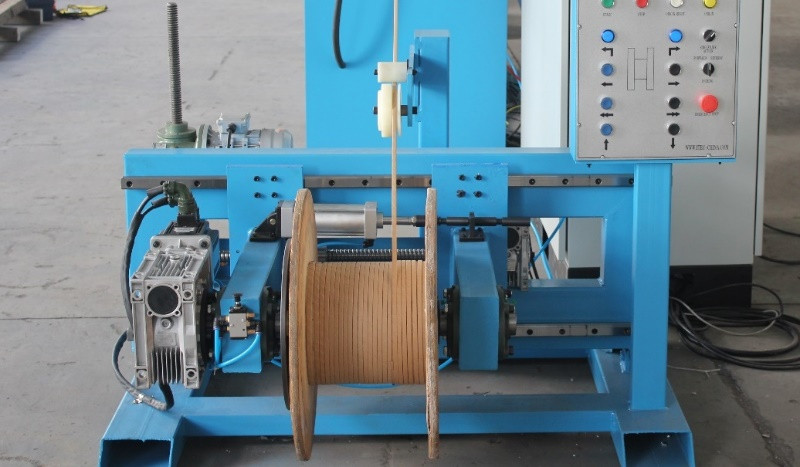

OEM/ODM China Magnet Wire Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng

OEM/ODM China Magnet Wire Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng Detail:

Main technical data

Conductor area: 5 mm²—120mm²(or customized)

Covering layer: 2 or 4 times of layers

Rotating speed: max. 1000 rpm

Line speed: max. 30 m/min.

Pitch accuracy: ±0.05 mm

Taping pitch: 4~40 mm, step less adjustable

Special Characteristics

-Servo drive for the taping head

-Rigid and modular structure design to eliminate vibration interaction

-Taping pitch and speed easy adjusted by touch screen

-PLC control and touch screen operation

Overview

Taping head

Caterpillar

Take-up

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for OEM/ODM China Magnet Wire Taping Machine - Horizontal Taping Machine-Single Conductor PengSheng , The product will supply to all over the world, such as: Philippines, Ukraine, Borussia Dortmund, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.

Write your message here and send it to us