OEM/ODM Manufacturer Steel Strand Production Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng

OEM/ODM Manufacturer Steel Strand Production Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng Detail:

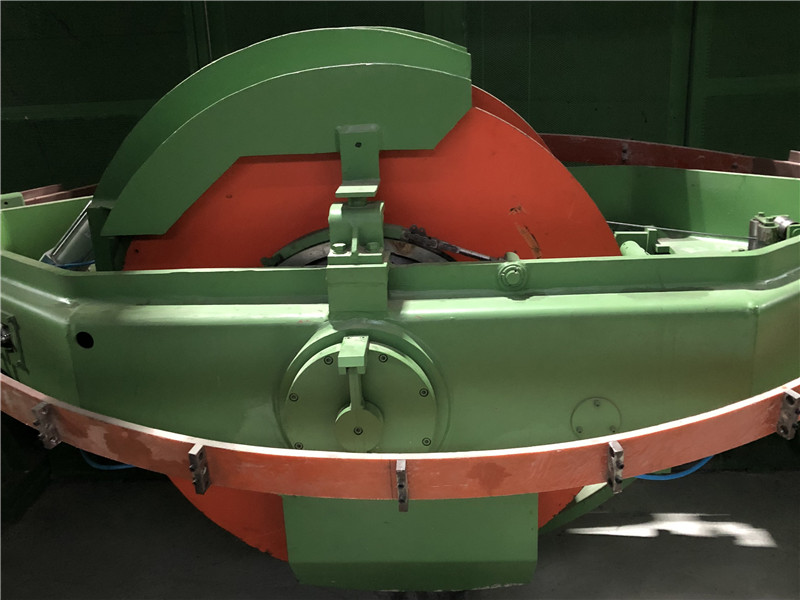

● Bow skip type strander to produce international standard strands.

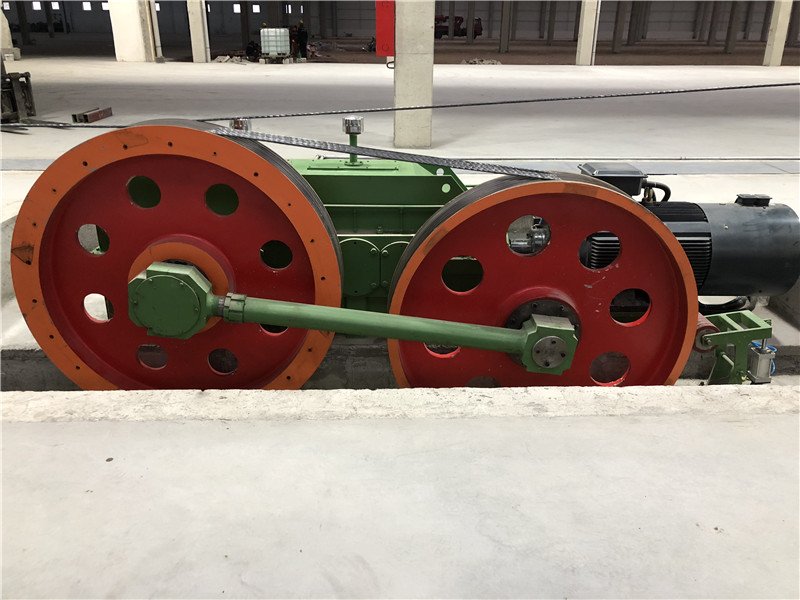

● Double couple of pulling capstan up to 16 tons force.

● Movable induction furnace for wire thermo mechanical stabilization

● High efficiency water tank for wire cooling

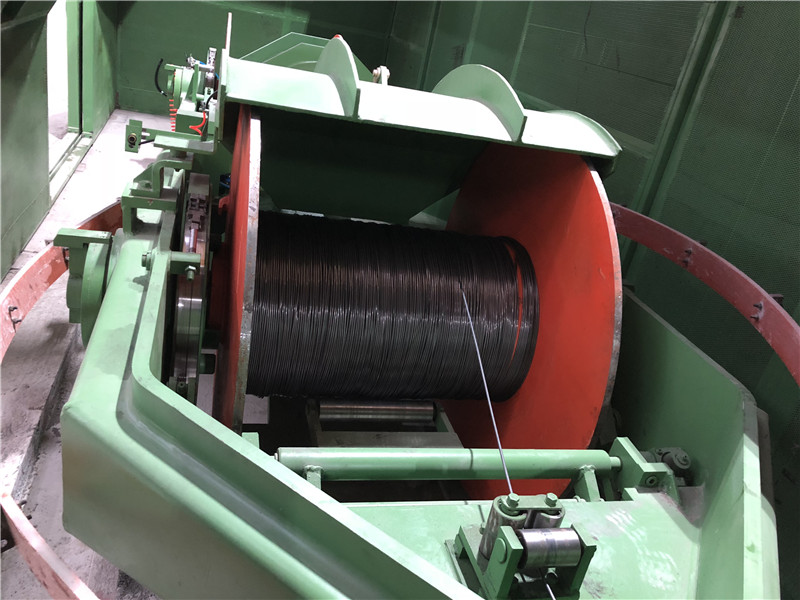

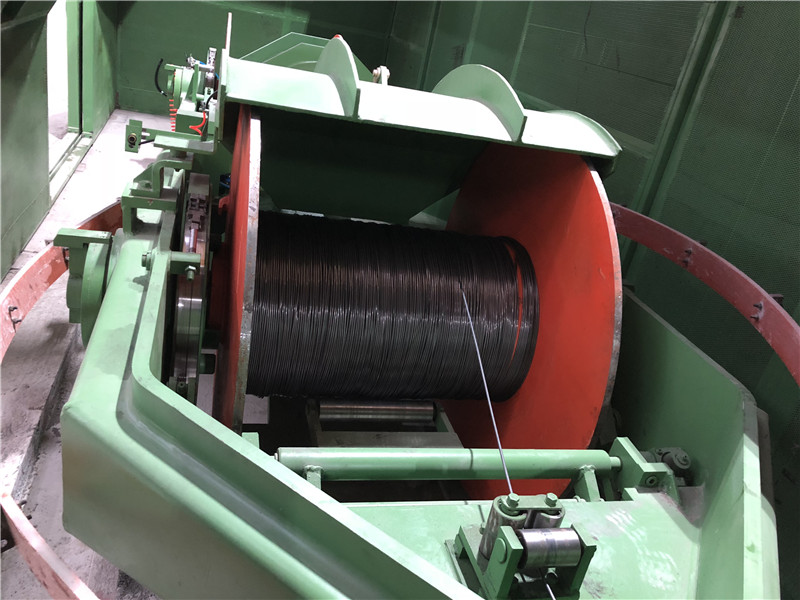

● Double spool take-up/pay-off (The first working as take-up and the second working as pay-off for rewinder)

|

Item |

Unit |

Specification |

|

Strand product size |

mm |

9.53; 11.1; 12.7; 15.24; 17.8 |

|

Line working speed |

m/min |

100m/min for 15.24mm |

|

Tension wheel diameter |

mm |

2200 |

|

Heating furnace power |

KW |

600 |

|

Heating temperature |

℃ |

370-420 |

|

Spool size of take-up and pay-off |

mm |

2700mm*1200mm*1400mm |

|

Rewinding speed |

m/min |

250 |

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for OEM/ODM Manufacturer Steel Strand Production Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng , The product will supply to all over the world, such as: Germany, United Arab emirates, Honduras, We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

Write your message here and send it to us