OEM/ODM Manufacturer Steel Strand Production Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng

OEM/ODM Manufacturer Steel Strand Production Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng Detail:

● Bow skip type strander to produce international standard strands.

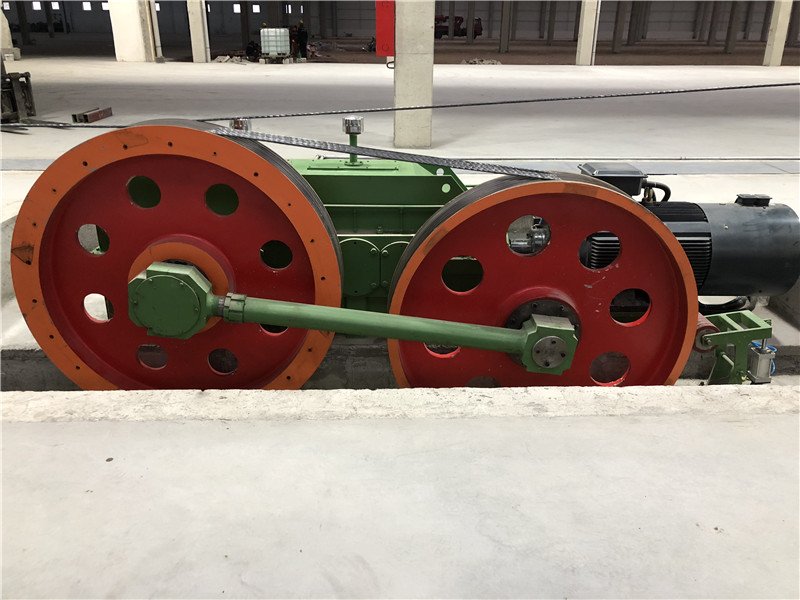

● Double couple of pulling capstan up to 16 tons force.

● Movable induction furnace for wire thermo mechanical stabilization

● High efficiency water tank for wire cooling

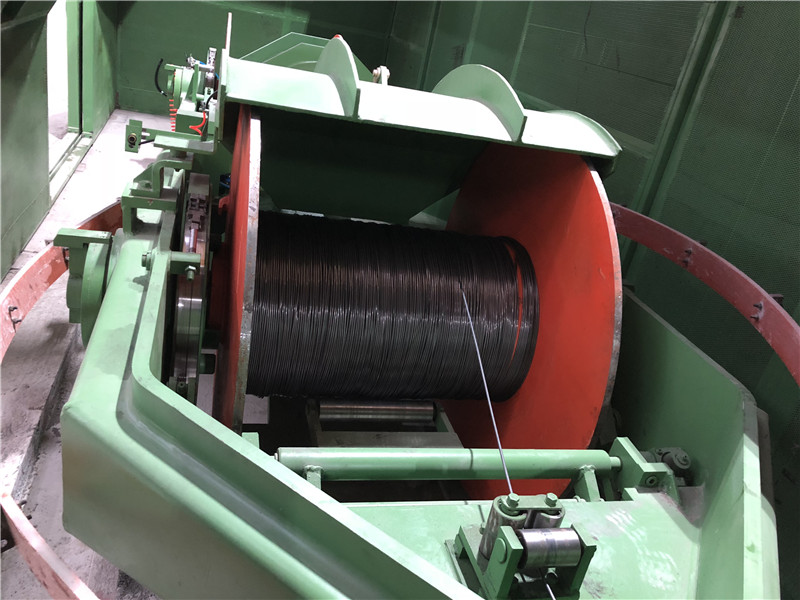

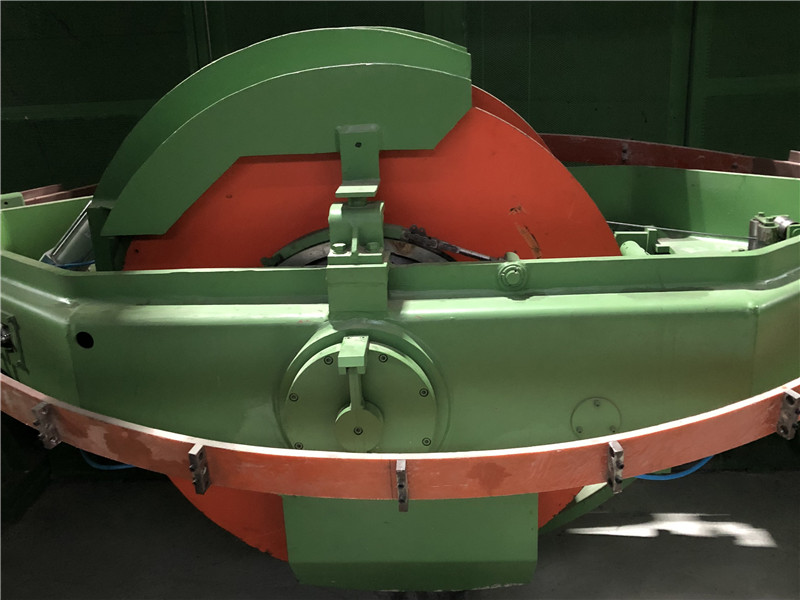

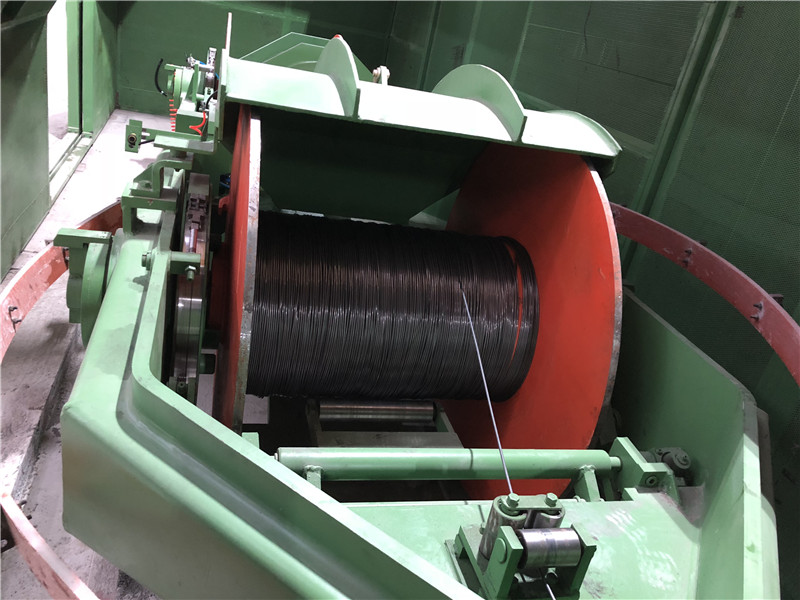

● Double spool take-up/pay-off (The first working as take-up and the second working as pay-off for rewinder)

|

Item |

Unit |

Specification |

|

Strand product size |

mm |

9.53; 11.1; 12.7; 15.24; 17.8 |

|

Line working speed |

m/min |

100m/min for 15.24mm |

|

Tension wheel diameter |

mm |

2200 |

|

Heating furnace power |

KW |

600 |

|

Heating temperature |

℃ |

370-420 |

|

Spool size of take-up and pay-off |

mm |

2700mm*1200mm*1400mm |

|

Rewinding speed |

m/min |

250 |

Product detail pictures:

Related Product Guide:

Our company promises all buyers of the first-class products and solutions as well as most satisfying post-sale support. We warmly welcome our regular and new shoppers to join us for OEM/ODM Manufacturer Steel Strand Production Line - Prestressed Concrete (PC) Bow Skip Stranding Line PengSheng , The product will supply to all over the world, such as: Indonesia, Yemen, Greece, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Write your message here and send it to us