OEM/ODM Supplier PC Steel Strand Making Machine - Continuous Cladding Machinery PengSheng

OEM/ODM Supplier PC Steel Strand Making Machine - Continuous Cladding Machinery PengSheng Detail:

Principle

The principle of continuous cladding/sheathing is similar with that of continuous extrusion. Using tangential tooling arrangement, the extrusion wheel drives two rods into the cladding/sheathing chamber. Under the high temperature and pressure, the material either reaches the condition for metallurgical bonding and forms a metal protective layer to directly clad the metal wire core that enters the chamber (cladding), or is extruded through the space between mandrel and cavity die to form a metal sheath without contacting the wire core (sheathing). Double-wheel cladding/sheathing uses two extrusion wheels to provide four rods to clad/sheath large diameter wire core.

| Model | SLB 350 | SLB400 | SSLB500(Double wheels) |

| Cladding | |||

| main motor power(kw) | 200 | 400 | - |

| feeding rod dia. (mm) | 2*9.5 | 2*12 | - |

| core wire dia. (mm) | 3-7 | 3-7 | - |

| line speed (m/min) | 180 | 180 | - |

| Sheathing | |||

| main motor power(kw) | 160 | 250 | 600 |

| feeding rod dia. (mm) | 2*9.5 | 2*9.5/2*12 | 4*15 |

| core wire dia. (mm) | 4-28 | 8-46 | 50-160 |

| sheath thickness (mm) | 0.6-3 | 0.6-3 | 2-4 |

| sheath outer dia. (mm) | 6-30 | 20-50 | 60-180 |

| line speed (m/min) | 60 | 60 | 12 |

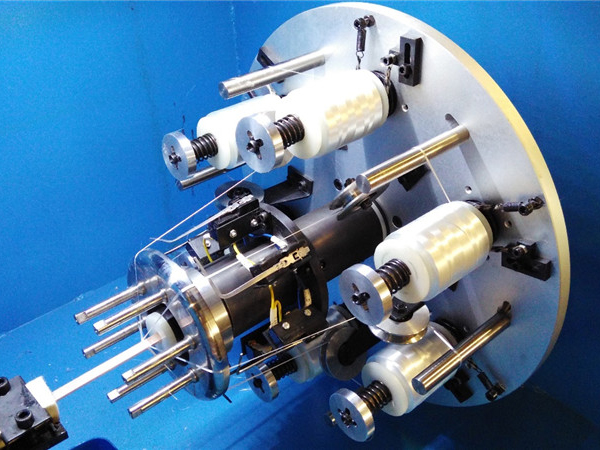

Product detail pictures:

Related Product Guide:

It can be our accountability to satisfy your preferences and competently provide you. Your satisfaction is our greatest reward. We are searching ahead towards your visit for joint growth for OEM/ODM Supplier PC Steel Strand Making Machine - Continuous Cladding Machinery PengSheng , The product will supply to all over the world, such as: Croatia, Holland, USA, With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.

Write your message here and send it to us