PriceList for Horizontal Concentric Taping Machine - Fiber Glass Insulating Machine PengSheng

PriceList for Horizontal Concentric Taping Machine - Fiber Glass Insulating Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 800 rpm

Line speed: max. 8 m/min.

Special Characteristics

Servo drive for the winding head

Auto-stop when fiberglass broken

Rigid and modular structure design to eliminate vibration interaction

PLC control and touch screen operation

Overview

Taping

Oven

Product

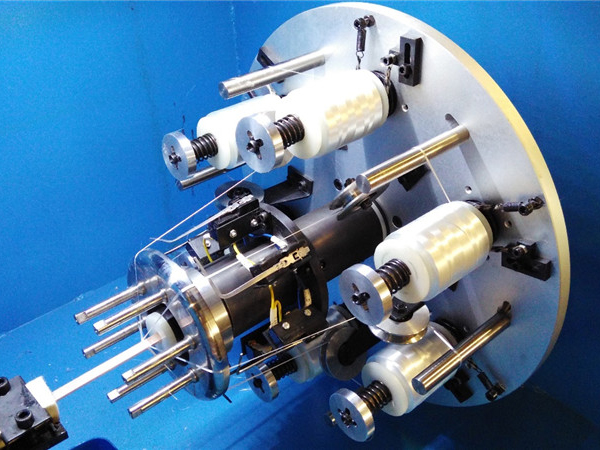

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for PriceList for Horizontal Concentric Taping Machine - Fiber Glass Insulating Machine PengSheng , The product will supply to all over the world, such as: Serbia, Nicaragua, Lisbon, Our solutions have national accreditation requirements for qualified, good quality items, affordable value, was welcomed by individuals all over the world. Our goods will continue to improve inside the order and appear forward to cooperation with you, Really should any of those items be of interest to you, please letus know. We will be satisfied to provide you a quotation up on receipt of the detailed needs.

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!

Write your message here and send it to us