PriceList for Horizontal Concentric Taping Machine - Fiber Glass Insulating Machine PengSheng

PriceList for Horizontal Concentric Taping Machine - Fiber Glass Insulating Machine PengSheng Detail:

Main technical data

Round conductor diameter: 2.5mm—6.0mm

Flat conductor area: 5mm²—80 mm²(Width: 4mm-16mm, Thickness: 0.8mm-5.0mm)

Rotating speed: max. 800 rpm

Line speed: max. 8 m/min.

Special Characteristics

Servo drive for the winding head

Auto-stop when fiberglass broken

Rigid and modular structure design to eliminate vibration interaction

PLC control and touch screen operation

Overview

Taping

Oven

Product

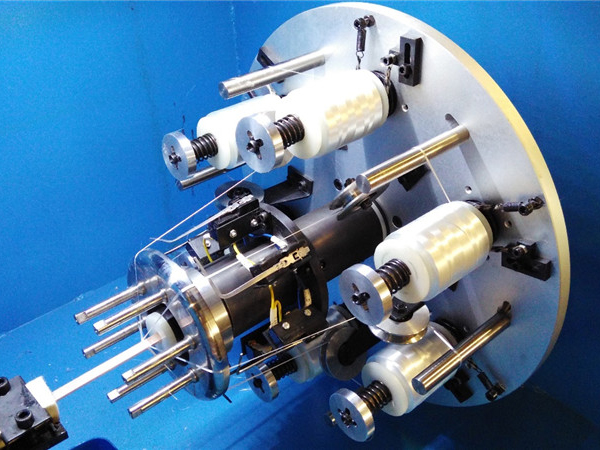

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of PriceList for Horizontal Concentric Taping Machine - Fiber Glass Insulating Machine PengSheng , The product will supply to all over the world, such as: Armenia, Islamabad, Malaysia, Our mission is "Provide Goods with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Write your message here and send it to us